1. Can the “anti-UV” performance of PVC tarpaulin really resist UV erosion in different environments?

When it comes to anti-UV PVC tarpaulin, "anti-UV" is the core label, but the intensity of ultraviolet rays in different scenarios varies greatly, such as strong ultraviolet rays in plateau areas, ultraviolet rays accompanied by salt spray in coastal areas, and outdoor ultraviolet rays in ordinary cities. Can the product fully resist the erosion of these different environments? In fact, high-quality anti-UV PVC waterproof tarpaulin does not only rely on a single coating to achieve anti-UV effect, but is guaranteed by the optimization of raw material formula and process upgrade: During the production stage of the PVC base cloth, anti-UV stabilizers will be added to improve the anti-aging ability from within the material; the surface coating will use a special formula to form a UV blocking layer to reduce UV penetration.

Different scenarios have different requirements for “anti-UV” performance. For example, when used for outdoor tents and awnings, the tarpaulin needs to be exposed to the sun for a long time. It must not only resist fading and cracking caused by ultraviolet rays, but also maintain good light transmittance (if necessary); when used for covering agricultural greenhouses, it must block harmful ultraviolet rays while ensuring the transmission of beneficial light required for crop growth; when used for outdoor transportation covering of trucks and containers, in addition to UV resistance, it must also be waterproof and tear-resistant to avoid a decrease in fabric strength due to ultraviolet aging. As a professional PVC tarpaulin manufacturer, Qidong Good Tarpaulin Co., Ltd. produces anti-UV coated fabrics that adjust the UV resistance level according to scene needs. For example, products for plateau outdoor tents have an anti-UV coefficient of up to UPF50+, effectively blocking more than 98% of UV rays. Products used for truck covers and trailer covers will have enhanced wear resistance and stretch resistance on the basis of UV resistance to adapt to long-term outdoor transportation environments.

2. The application scenarios of UV resistant PVC tarpaulin are far more than "sunshade". In which subdivided scenarios can it still exert its value?

Many people think that the role of UV resistant PVC tarpaulin is only to "shade the sun", but in fact it can play a key role in multiple segmented scenarios with its composite properties of "anti-UV + waterproof + durability". For example, in the agricultural field, in addition to common awnings, "anti-UV and rain-proof sheds" can also be used for fruit and vegetable cultivation - blocking strong ultraviolet rays in summer to avoid burning fruits and vegetables, and preventing rain soaking in rainy seasons from causing fruit rot. At the same time, the breathability of the fabric can also ensure ventilation in the shed and reduce pests and diseases; in the field of aquaculture, "anti-UV" can be used for fish ponds. "Waterproof Covering Film" prevents excessive algae reproduction in water bodies caused by direct ultraviolet rays, and prevents rainwater erosion from changing the salinity and pH of water bodies; in the field of outdoor equipment storage, outdoor protective covers for large machinery (such as excavators and cranes) not only block ultraviolet rays from aging equipment shells and wires, but are also waterproof and dustproof to prevent internal parts of the equipment from getting damp and rusting.

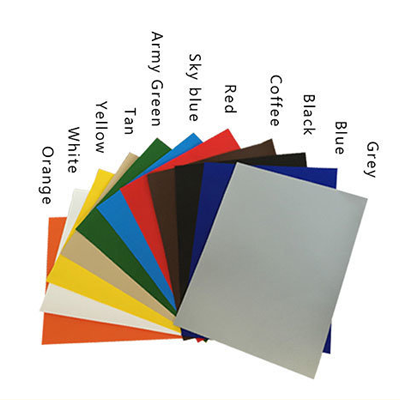

In addition, in leisure and entertainment scenarios, the application of UV resistant PVC tarpaulins is also being upgraded. For example, the "portable anti-UV canopy" for camping can not only provide sunshade, but also temporarily block rain during sudden rainfall, and the fabric is lightweight and easy to store; the outdoor rest area awnings in scenic spots will use brightly colored and anti-UV fabrics, which not only meets the aesthetic needs, but also ensures that tourists stay for a long time without being sunburned by ultraviolet rays. Qidong Good Tarpaulin has also expanded its UV-resistant PVC fabrics to multiple segmented products. In addition to traditional truck covers and container tarpaulins, it can also customize agricultural greenhouse coverings, camping canopies, outdoor equipment protective covers, etc. It can even produce special finished products such as pet doors and industrial curtains according to customer needs, allowing anti-UV properties to be implemented in more scenarios.

3. When customizing UV resistant PVC tarpaulin, in addition to size, what key requirements need to be clarified to avoid "mismatching"?

When customizing UV resistant PVC tarpaulins, many users only focus on “whether the size is appropriate” but ignore other key requirements, resulting in a “mismatch” between the finished product and the actual scene. In fact, the requirements that need to be clarified before customization are far more than size. The first is "UV resistance level" - it needs to be selected according to the UV intensity of the usage scenario. For example, short-term outdoor coverage in ordinary cities (such as temporary warehousing) can choose UPF30+ products, while long-term outdoor use in plateau and tropical areas (such as truck covers parked in the open all year round) requires UPF50+; secondly, "additional function priority" - if the scene requires both waterproof and anti- For UV, it is necessary to clarify the waterproof level (such as whether it needs to withstand heavy rain and immersion). If it is used for mechanical covering, it is also necessary to clarify whether it needs to be resistant to oil stains and chemical reagents to prevent the fabric from being corroded by oil stains leaked from the equipment. The third step is the "installation and use details" - for example, if it is used for large equipment protective covers, whether access openings and ventilation holes need to be reserved, and if it is used for truck covering, whether it needs to be equipped with ropes and hooks for easy fixing. These details will directly affect the convenience of use.

In addition, "environmental tolerance" also needs to be considered in advance. For example, UV-resistant tarpaulins used in coastal areas need additional requirements for "anti-salt spray corrosion" to prevent the salt spray from evaporating seawater from accelerating the aging of the fabric; when used in low-temperature areas, "low-temperature resistance" needs to be considered to prevent the fabric from becoming hard and brittle in winter. The customized services provided by Qidong Good Tarpaulin will fully cover these needs. Its team will first understand the customer's specific application scenarios (such as outdoor warehousing, agricultural planting, logistics and transportation, etc.), and then recommend appropriate anti-UV levels, additional functions and processes based on the scene details. For example, container tarpaulins customized for customers in coastal areas will add anti-UV stabilizers and anti-salt spray coatings at the same time to ensure that the products can still be used for a long time in high salt spray and strong UV environments, truly realizing "customization on demand to avoid mismatching."

4. How to judge whether the “anti-UV performance” of anti-UV PVC tarpaulin has expired after long-term use?

The "anti-UV performance" of anti-UV PVC tarpaulin is not permanently effective. After long-term use, it will gradually decay due to accumulated ultraviolet rays, environmental erosion, etc. So how to judge whether its performance has failed? First, through "appearance observation" - if there is obvious fading on the surface of the oilcloth (such as the original bright color becoming dull and uneven), coating peeling off (powder-like substances fall off when touched by hand), or fabric cracking (especially small cracks at the corners and folds), it means that the anti-UV coating has been damaged and the internal base fabric has begun to age; secondly, it can be passed through the "handle and strength test" - If the oilcloth becomes stiff and brittle, wrinkles will easily appear and are difficult to recover when gently pulled, or fibers will break after rubbing hard, it means that the fabric's toughness and strength have decreased due to UV aging, and its UV resistance has been greatly weakened.

In addition, it can also be judged indirectly through the "waterproof performance" - anti-UV coating and waterproof coating are often related to each other. If the originally waterproof tarpaulin begins to seep water (for example, water droplets penetrate into the inside after rain), it may be that after the anti-UV coating ages and cracks, moisture enters the inside of the fabric and destroys the waterproof structure, which indirectly indicates that the anti-UV performance has failed. When these situations occur, it is recommended to replace the tarpaulin in time to avoid damage to the covered goods and equipment due to protection failure. The anti-UV products produced by Qidong Good Tarpaulin will be marked with a recommended service life (usually 3-5 years depending on the scenario) when leaving the factory, and guidance on regular inspection and maintenance will be provided to help users discover signs of performance degradation in a timely manner and ensure safe use.