I. The core of PVC Laminated Tarpaulin: Type 3 composite technology and performance characteristics

The composite process determines the interlayer bonding strength, performance balance and scene adaptability of PVC Laminated Tarpaulin. Currently, mainstream processes can be divided into three categories. The technical logic and performance focus of each type of process are significantly different:

1. Hot Press Lamination: The layers are tight and suitable for medium and high frequency use

The hot-pressing lamination process uses high temperature (120-160°C) and high pressure (0.3-0.5MPa) to press the PVC film and base cloth (usually polyester or nylon cloth) between pressure rollers. The hot-melt properties of the PVC film are used to achieve interlayer adhesion without the need for additional adhesives. Its typical structure is a sandwich structure of "PVC film + base fabric + PVC film". The thickness is usually 0.6-1.0mm. The core advantages are:

① High inter-layer bonding strength: hot melt bonding without adhesive layer, inter-layer peeling strength ≥5N/25mm, far exceeding coated tarpaulin (≤3N/25mm), long-term use is not prone to delamination and wrinkles;

② Balanced performance: Double-sided PVC film ensures consistent waterproof and wear-resistant performance on both front and back sides, without the problem of "uneven coating thickness", and is suitable for scenarios that require double-sided use (such as reversible cargo coverings, double-sided awnings);

③ Excellent temperature resistance: The hot pressing process can improve the crystallinity of the PVC film, and the temperature resistance range is widened to - 25°C to 70°C. Under high-temperature exposure or low-temperature environments, the structural stability is better than ordinary coated tarpaulins.

However, the hot-pressing composite process has high requirements for the flatness of the base fabric (a flatness error of ≤0.1mm/m is required), and it cannot composite overly thick functional layers (such as insulation layers exceeding 0.3mm). It is suitable for scenarios that require "stable structure + consistent performance on both sides", such as medium-sized truck tarpaulins, outdoor temporary warehouse tarpaulins, etc.

2. Adhesive Lamination: Flexible lamination to meet multi-functional needs

The adhesive composite process applies a special adhesive (such as polyurethane glue, acrylic glue) between the PVC film and the base fabric (or multi-layer material), and then dries and presses them to achieve inter-layer bonding. It can flexibly combine a variety of functional materials to form a multi-layer structure of "PVC film + functional layer + base fabric + PVC film". The thickness can be customized from 0.8-1.5mm. Its core advantages are:

① Functional diversity: The thermal insulation layer, flame retardant layer, and anti-static layer can be combined to achieve multiple performance superpositions such as "waterproof + thermal insulation + flame retardant" to adapt to complex scenarios;

② Suitable for a variety of substrates: no high temperature is required, temperature-sensitive materials (such as PVC film and cotton base cloth) can be combined to broaden the range of substrate choices;

③ Wide thickness controllable range: By increasing the number of functional layers, thicker products of more than 1.5mm can be achieved to meet heavy-duty protection needs (such as long-term protective covers for large equipment).

The limitations are: the adhesive layer may be affected by high temperature and high humidity environments, and may peel off between layers after long-term use (more than 5 years). The adhesive contains trace amounts of VOC (volatile organic compounds). It is necessary to choose an environmentally friendly adhesive (such as solvent-free polyurethane glue) to reduce environmental impact. The adhesive composite process is suitable for scenarios that require "multi-functional superposition", such as cold chain transportation insulation tarpaulins, flame-retardant industrial equipment covers, etc.

3. Extrusion Lamination: efficient mass production, suitable for large quantities of standard products

The extrusion compounding process melts the PVC resin through an extruder and then directly extrudes it on the surface of the base fabric, while compounding another layer of PVC film to form a structure of "PVC film + molten PVC layer + base fabric". The production speed is fast (up to 30-50 meters/minute), and it is suitable for large-volume standardized products (such as uniform-size cargo covering fabrics, ordinary outdoor awning fabrics). Its core advantages are:

① High production efficiency: integrated extrusion + compounding is 2-3 times more efficient than the hot pressing process, and mass production costs are reduced by 15%-20%;

② Seamless coating: The molten PVC layer is continuously extruded, eliminating the "scratching seam" problem of uncoated tarpaulin, and the waterproofing is more stable;

③ The base fabric has strong adaptability: it can be adapted to medium and low density base fabrics (such as 6×6 fibers/cm polyester fabric), reducing base material costs while ensuring basic protective performance.

However, the interlayer bonding strength of the extrusion composite process is low (peel strength ≥3.5N/25mm), and functional layers cannot be composited. It is suitable for high-volume scenarios that require "cost-sensitive + basic waterproofing and wear resistance", such as agricultural greenhouse auxiliary tarpaulins, short-term cargo transportation covering cloths, etc.

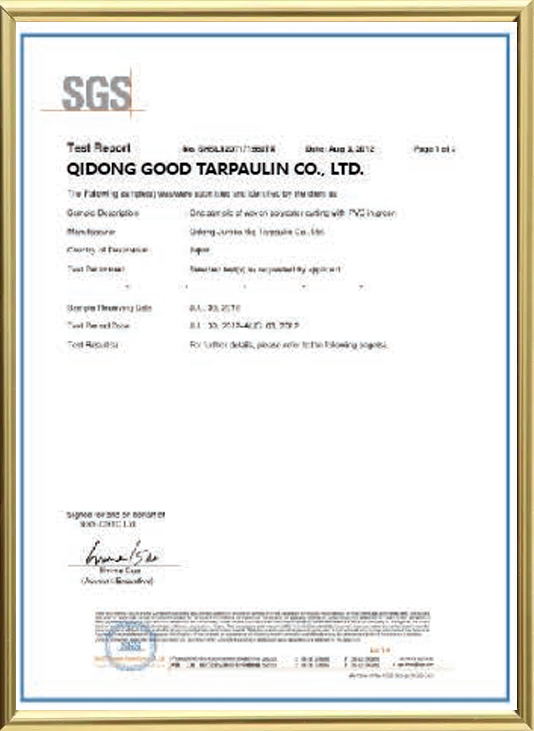

Professional manufacturers such as Qidong Good Tarpaulin, which has 3 extrusion lamination production lines and 2 adhesive lamination production lines, can flexibly choose processes according to customer needs: hot pressing lamination is used for high-quality double-sided tarpaulins, adhesive lamination is used for multi-functional customized products, and extrusion lamination is used for large-volume standard products. By optimizing process parameters (such as hot pressing temperature 145℃, adhesive solid content ≥50%), ensuring the interlayer bonding strength and durability of various types of composite tarpaulins. The outdoor service life of its hot-pressed composite truck tarpaulins can reach 7-8 years, and the thermal insulation performance of adhesive composite thermal insulation tarpaulins also far exceeds the industry average.

II. PVC Laminated vs PVC Coated: 3 core differences, choose right or wrong

Many users confuse PVC Laminated Tarpaulin and PVC Coated Tarpaulin. In fact, there are essential differences between the two in structure, performance, and scene adaptation. Accurate differentiation is the key to selection:

1. Structural differences: “Layered composite” vs “Coating coverage”

PVC Laminated Tarpaulin: The core is a "multi-layer structure", which is composed of PVC film and base fabric (or functional layer) combined through a composite process. Each layer is independent and synergistic, such as "PVC film (waterproof) + base fabric (tear-resistant) + PVC film (wear-resistant)", and the structure is similar to a "sandwich";

PVC Coated Tarpaulin: The core is "coating coverage". PVC slurry is coated on the surface of the base fabric to form a two-layer structure of "base fabric + coating". The coating and base fabric have a "covering-covered" relationship, and there is no independent functional layer.

Structural differences are a direct result: composite tarpaulins can achieve multi-performance stacking by adding functional layers, while coated tarpaulins can only achieve single performance optimization by adjusting the coating formula (such as adding anti-UV agents to improve weather resistance).

2. Performance difference: "Balanced and stable" vs "Single point prominent"

Balanced performance: The multi-layer structure of the composite tarpaulin makes the performance more balanced. For example, the waterproofness and wear resistance of the hot-pressed composite tarpaulin are consistent on both sides, and there is no problem of "thick coating on one side and thin on one side"; the performance of the coated tarpaulin depends on the thickness of the coating, and there may be a situation where "the front side is waterproof but the back side is poor";

Functional scalability: Composite tarpaulins can be combined with functional layers such as thermal insulation and flame retardant through the adhesive process to achieve "one cloth with multiple functions"; coated tarpaulins can only add additives (such as flame retardants) to the coating, and the functional improvement is limited (for example, adding more than 30% of the coating's flame retardants will cause the coating to become brittle);

Durability: The interlayer bonding strength of composite tarpaulin (hot pressing process ≥5N/25mm) is higher than that of coated tarpaulin (≤3N/25mm), and it is not easy to delaminate after long-term use; however, the coating and base fabric of coated tarpaulin are "penetrated combination" (such as dip coating process), and in corrosive environments (such as acid and alkali), the peeling resistance is better than ordinary adhesive composite tarpaulin.

3. Differences in scenarios: “Complex multiple requirements” vs “Single basic requirement”

PVC Laminated Tarpaulin: suitable for scenarios that require "multiple performance + structural stability", such as cold chain transportation (waterproof + thermal insulation), flame-retardant industrial equipment covers (waterproof + flame-retardant), double-sided outdoor tarpaulins (double-sided wear-resistant + waterproof);

PVC Coated Tarpaulin: Suitable for scenes with demand for "single outstanding performance + cost sensitivity", such as ordinary outdoor sunshade (waterproof + anti-UV), chemical equipment cover (acid and alkali resistance + waterproof), and light cargo coverage (basic waterproof + wear resistance).

For example: "Cold chain truck transportation in Southeast Asia needs to be waterproof, thermal insulation, and resistant to high-frequency loading and unloading friction" - choose adhesive composite PVC insulation tarpaulin; "Ordinary outdoor warehouse shading only requires basic waterproofing and anti-UV" - choose PVC-coated tarpaulin with scratch coating process, which is lower cost.

III. How to choose PVC Laminated Tarpaulin? 4-step lock-in precise solution

Selection needs to be centered around "scenario requirements - process matching - performance verification" to avoid poor performance due to "process mismatch". The specific steps are as follows:

1. Clarify the core requirements of the scene and eliminate inappropriate processes

Based on the “core requirements + secondary requirements” of the scenario, the composite process is initially locked:

If the requirement is "consistent performance on both sides + stable structure" (such as tarpaulin used on both sides), and there is no multi-functional requirement - choose the hot pressing composite process;

If the requirement is "multi-performance superposition" (such as waterproof + thermal insulation + flame retardant), and the temperature resistance requirements are not high (≤60℃) - choose the adhesive composite process (environmentally friendly adhesives are required);

If the requirement is "basic waterproofing and wear-resistance" and you need to purchase in large quantities (such as more than 1,000 square meters at a time) - choose the extrusion composite process, which is more cost-effective.

For example: "The tarpaulin for cold chain logistics vehicles in northern winter needs to be waterproof, heat-insulating (no freezing at -30°C), and friction-resistant" - the core requirement is "waterproof + heat preservation", and the secondary requirement is "low-temperature resistance + abrasion resistance". Extrusion compounding (the insulation layer cannot be compounded) is excluded, and the adhesive compounding process is selected. Qidong Good Tarpaulin can provide customized solutions according to this demand to ensure that the insulation performance meets the standards.

2. Verify key performance indicators to avoid inferior products

The core quality of composite tarpaulin is "interlayer bonding strength" and "functional layer performance". No professional equipment is required, and it can be preliminarily verified through the following methods:

Inter-layer bonding strength: Grasp the two layers of the composite tarp (such as PVC film and base fabric) with your hands and tear it hard. There will be no signs of delamination in high-quality products; "separation of the film and base fabric" may occur in inferior products, and even adhesive residues can be seen;

Functional layer performance: If it is a thermal insulation composite tarpaulin, you can compare the weight at the same thickness (composite tarpaulins with high-quality thermal insulation layer have better thermal insulation); if it is a flame-retardant composite tarpaulin, you can use a lighter to lightly burn it (high-quality products are extinguished immediately after leaving the fire, without dripping; inferior products will melt and drip after burning);

Waterproofness: Pour water on the surface of the composite tarpaulin and observe whether complete water droplets form (no diffusion); then turn the tarpaulin over and test. The waterproofness on both sides should be consistent (hot pressing/adhesive composite process).

3. Pay attention to the matching between the base material and the composite process

The base material is the "skeleton" of the composite tarpaulin, and its matching with the process directly affects the performance:

Hot pressing composite process: It is necessary to choose a high-density, flat polyester base fabric (such as 10×10 pieces/cm, flatness ≤0.1mm/m) to avoid uneven hot pressing and local delamination caused by uneven base fabrics;

Adhesive composite process: If the insulation layer is composited, a PVC film with low surface tension (surface tension ≤34mN/m) needs to be selected to ensure that the adhesive can be fully infiltrated and improve the bonding strength between layers;

Extrusion composite process: You can choose medium and low density base fabric (such as 6×8 fibers/cm), but you need to ensure that the breaking strength of the base fabric is ≥1200N/meter to avoid overall tearing due to insufficient strength of the base fabric after compounding.

Inferior products often have the problem of "high craftsmanship + low base material". For example, a low-density base fabric (5×5 fibers/cm) is composited with a hot-pressing process. It seems to have a stable structure, but in fact the base fabric has insufficient support and poor tear resistance. When purchasing, the manufacturer must provide base material parameters (such as base fabric density, breaking strength).

4. Choose “Standard Style” or “Customized Style” as needed

Standard model: suitable for regular scenes (such as ordinary truck tarpaulins, outdoor awning tarpaulins), such as Qidong Good Tarpaulin's hot-pressed composite standard tarpaulin (0.8mm thick, double-sided PVC film + polyester base fabric), with sufficient stock in stock, and can be shipped in 3-5 days. The price is 10%-15% lower than the customized model;

Customized model: Suitable for special scenarios (such as thermal insulation, flame retardant, anti-static), detailed demand parameters need to be provided (such as "insulation tarpaulin needs to meet specific thermal insulation standards, and flame retardancy needs to reach UL94 V-0"). The manufacturer designs composite structures and processes according to needs. For example, Qidong Good Tarpaulin's customized service can provide full-process support of "structural design - sample production - performance testing - mass production", and the sample production cycle is 7-10 days to ensure that it meets the needs of the scene.

IV. Scenario-based application of PVC Laminated Tarpaulin: process adaptation, maximizing efficiency

Tarpaulins with different composite processes need to be used in combination with their structural characteristics to give full play to their performance advantages:

1. Hot pressing composite products: double-sided scene, focusing on “uniform force”

Double-sided awning/truck tarpaulin: When installing, ensure that the front and back sides of the tarpaulin are not upside down (although the performance is the same, the marked side is facing up for subsequent maintenance); when fixing, use evenly spaced buckles (one every 60cm) to avoid excessive local force that causes the PVC film to stretch and deform;

Outdoor temporary warehouse tarpaulin: A 5%-10% expansion margin needs to be reserved during construction (heat-pressed composite tarpaulins will expand and contract slightly when the temperature changes) to prevent the tarpaulin from being stretched and cracked due to too high or too low temperatures; roll it into a tube shape (not folded) when storing to reduce PVC film creases (creases can easily lead to accelerated local aging).

2. Adhesive composite products: multi-functional scenarios, focusing on “functional layer protection”

Cold chain thermal insulation tarpaulin: When using it, avoid poking it with sharp objects (such as the corners of goods) to prevent damage to the insulation layer (once damaged, the insulation performance will drop by more than 30%); when cleaning, wipe it gently with a neutral detergent (such as soapy water), and do not use a high-pressure water gun (it may break the bonding between layers);

Flame-retardant industrial equipment cover: When installing, ensure that the tarpaulin completely covers the equipment, and the edges are fixed with flame-retardant ropes (avoid using ordinary nylon ropes, which are easy to burn at high temperatures); regularly check whether the flame-retardant layer is damaged, and if damage is found, it needs to be replaced in time (the damaged area has no flame-retardant effect and poses a safety hazard).

3. Extruded composite products: large-volume scenarios, focusing on “basic protection”

Auxiliary tarpaulin for agricultural greenhouses: avoid direct contact with sharp scaffolding when covering, and place soft cloth at the contact points; for long-term use (more than 3 years), it is necessary to check whether the PVC film has aged (such as surface brittleness and discoloration). If the aging is serious, it must be replaced in time to prevent rainwater penetration;

Short-term cargo covering cloth: Avoid dragging the tarpaulin when loading and unloading cargo (the bonding strength between extrusion composite layers is low, and dragging can easily lead to delamination), and should be lifted and handled with care; it should be stored away from high temperatures (≥70°C will cause the PVC film to soften and stick together).