1. What exactly is the “heavy duty” of heavy duty PVC tarpaulin? Can it really withstand the test of extreme scenes?

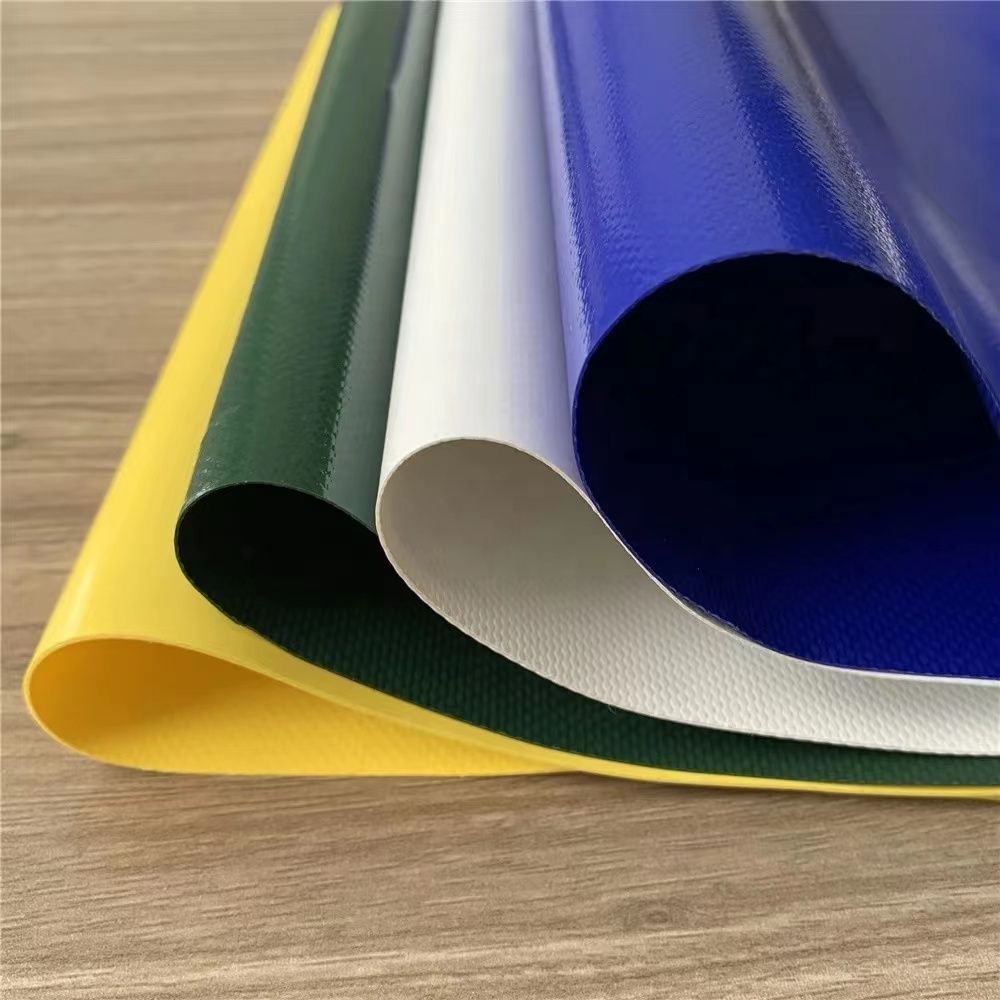

When it comes to heavy duty PVC tarpaulin, many people will intuitively think that "thicker means heavier and more durable", but the core advantage of "heavy-duty" goes far beyond thickness. Its "heavy-duty" characteristics are mainly achieved through three dimensions: first, the strength of the base fabric, which is woven with high-denier polyester fiber or nylon fiber. The tear resistance and tensile strength far exceed that of ordinary PVC tarpaulin. For example, the tear strength of ordinary tarpaulin is about 200N, while high-quality heavy-duty tarpaulin can reach more than 500N and can withstand the friction and pulling of large goods; the second is the coating process, which uses multi-layer PVC Coating technology, the coating thickness is uniform and the adhesion is strong, which not only improves the waterproof performance, but also enhances the wear resistance and puncture resistance of the fabric to prevent easy scratches by sharp objects; third, the edges and accessories are reinforced. The edges of the oilcloth will be double-stitched or hemmed, with metal buckles, reinforcing ropes and other accessories to prevent edge cracking during use and further improve the overall load-bearing capacity.

These properties allow heavy-duty PVC tarps to handle a variety of extreme scenarios. For example, in mining transportation scenarios, heavy-duty tarps used to cover large ores need to withstand the friction of sharp edges and corners of the ores, the pull of vehicles when bumps, and the double erosion of outdoor heavy rain and exposure to the sun; when stacked and covered in port containers, they need to withstand part of the pressure of the upper containers and resist the impact of strong winds brought by sea breeze; when heavy machinery (such as bulldozers and tower cranes) are stored outdoors, they need to cover the entire equipment to withstand the local pulling force caused by the weight of the machinery itself, and prevent dust and rainwater from entering the inside of the machinery. As a professional PVC tarpaulin manufacturer, Qidong Good Tarpaulin Co., Ltd. produces heavy duty PVC tarpaulins that have been rigorously tested in these dimensions. The base fabric is made of high-strength polyester fiber, and the coating thickness can reach 0.5-1.2mm. The edges are designed with thickened edges and high-strength metal buckles, which can easily cope with the test of extreme scenes such as mines, ports, and heavy machinery protection.

2. Are there clear boundaries for the application scenarios of heavy duty PVC tarpaulin? Which scenarios are more suitable to choose "Heavy" instead of "Normal"?

Many users are confused when choosing: "Does my scene require ordinary PVC tarpaulin or heavy duty PVC tarpaulin?" In fact, the application boundaries of the two mainly depend on the three factors of "stress intensity", "frequency of use" and "environmental severity". Not all scenarios require "heavy-duty", but it is recommended to give priority to heavy-duty products in the following types of scenarios. The first is "long-term high-frequency load-bearing scenarios", such as trucks and trailers used to transport heavy goods (such as steel, machinery and equipment) for a long time. The goods will continue to produce pressure and friction on the tarpaulin during the transportation process. Ordinary tarpaulin is prone to local wear or tear, while the high wear resistance and high tear resistance of heavy-duty tarpaulin can extend the service life; secondly, "Long-term covering scenarios in harsh outdoor environments", such as in outdoor areas such as oil fields and mines, are used to cover large equipment or raw materials. They need to withstand strong winds, heavy rains, and ultraviolet exposure for a long time, and may face accidents such as gravel impacts. The strong protective performance of heavy-duty tarpaulins can reduce the cost of frequent replacement; thirdly, "Large-scale covering scenarios", such as covering large storage sheds and outdoor temporary workshops. The tarpaulin itself has a large area and will produce a large pulling force under the action of wind. Ordinary tarpaulins are prone to cracking due to uneven stress, but the high tensile strength of heavy-duty tarpaulins can resist this pulling force and ensure the stability of the overall structure.

On the contrary, if the scene is "short-term temporary cover" (such as outdoor drying cover at home), "lightweight cargo protection" (such as covering clothing, small tools) or "indoor storage cover" (without wind, sun, and external impact), you can choose ordinary PVC tarpaulin. There is no need to excessively pursue "heavy duty" and cause waste of costs. Qidong Good Tarpaulin will also recommend suitable product types based on customers' scene needs, such as heavy-duty truck covers for truck customers who transport steel for a long time, and lightweight PVC tarpaulins for family camping customers, which not only ensures the use effect, but also avoids cost redundancy. At the same time, the heavy-duty PVC tarps produced by it can also be expanded to special scenarios, such as customized large machine covers, heavy-duty tarpaulins for port containers, mining raw material covering cloths, etc., further clarifying the application boundaries of heavy-duty products.

3. When customizing heavy duty PVC tarpaulins, in addition to conventional parameters, what “heavy-duty exclusive” requirements need to be confirmed?

When customizing heavy duty PVC tarpaulin, if you only provide conventional parameters such as size and color, it is likely that the finished product will not meet the core requirements of the "heavy-duty" scenario. Therefore, you need to additionally confirm the following "heavy-duty exclusive" requirements. The first is the "reinforcement requirements for stress points". Heavy tarpaulin will have clear stress points during use (such as the corners of truck covers and support points of large equipment covers). The location and estimated stress intensity of these stress points need to be informed to the custom manufacturer in advance so that the manufacturer can use special reinforcement processes, such as adding double-layer base cloth, adding metal reinforcement sheets or reinforcing ropes at the stress points to prevent damage caused by excessive local stress; secondly, "Balancing requirements between weight and flexibility". Although heavy-duty oilcloth requires high strength, some scenarios (such as truck covers that require frequent manual loading and unloading) also need to take into account a certain degree of flexibility to avoid manual operation difficulties due to excessive weight and hard materials. You can communicate with the manufacturer to adjust the ratio of base fabric and coating to ensure strength while optimizing flexibility; again "Special accessory adaptation requirements". Heavy tarpaulin often needs to be equipped with special accessories (such as high-strength binding tape, waterproof zippers, quick-fix buckles). It is necessary to confirm in advance whether the specifications and materials of the accessories match the tarpaulin. For example, whether the load-bearing capacity of the binding tape is consistent with the tensile strength of the tarpaulin to avoid failure of the tarpaulin due to breakage of accessories.

In addition, "special requirements for environmental adaptability" also need to be confirmed. For example, when using heavy-duty oilcloth in low-temperature areas, the fabric needs to have "low-temperature resistance toughness" to prevent the fabric from becoming hard and brittle due to low temperatures in winter; when used in chemical industry parks, the fabric needs to have "chemical corrosion resistance" properties to avoid coating shedding and base fabric aging after contact with chemical gases or liquids. The heavy-duty customization service provided by Qidong Good Tarpaulin will focus on these "exclusive" needs. Its technical team will have an in-depth understanding of the customer's specific usage scenarios (such as the location of stress points, operating methods, and environmental characteristics), design reinforcement solutions, adjust product formulas, and provide matching special accessories. For example, heavy-duty machine covers customized for customers in low-temperature areas will add low-temperature resistant plasticizers to the PVC coating, and tarpaulins customized for customers in chemical industry parks will use anti-corrosion coatings to ensure that the finished products are fully suitable for "heavy-duty" scenarios.

4. The quality of "heavy duty PVC tarpaulin" on the market varies. How to quickly identify whether it really "qualifies"?

Faced with PVC tarpaulins on the market that are labeled as “heavy-duty” but are of substandard quality, ordinary users can quickly identify them through three simple methods: “see, measure, and check.” The first is to "look at the details". The appearance of high-quality heavy-duty oilcloth has obvious characteristics: the base fabric has a clear texture and uniform density, without obvious jumps or holes; the coating surface is flat and smooth, without bubbles, impurities or local uneven thickness; the edges are neatly processed, the hemming lines are straight, and accessories such as metal buckles and reinforcing ropes are firmly connected to the oilcloth without looseness or gaps. If you find that the surface of the oilcloth is rough, the edges are frizzy, or the accessories are loosely connected, it is likely to be a low-quality product. The second is the "simple test", which can judge the strength through two small tests: the first is the "tensile test", grab both ends of the oilcloth with your hands and pull it gently. The high-quality heavy-duty oilcloth will not show obvious deformation and can quickly return to its original shape after letting go, while inferior products may have tensile deformation or wrinkles; the second is the "wear-resistant test", use a key or coin to gently scratch the surface of the oilcloth. The coating of high-quality products will not easily fall off or scratches, while the coating of inferior products may be damaged.

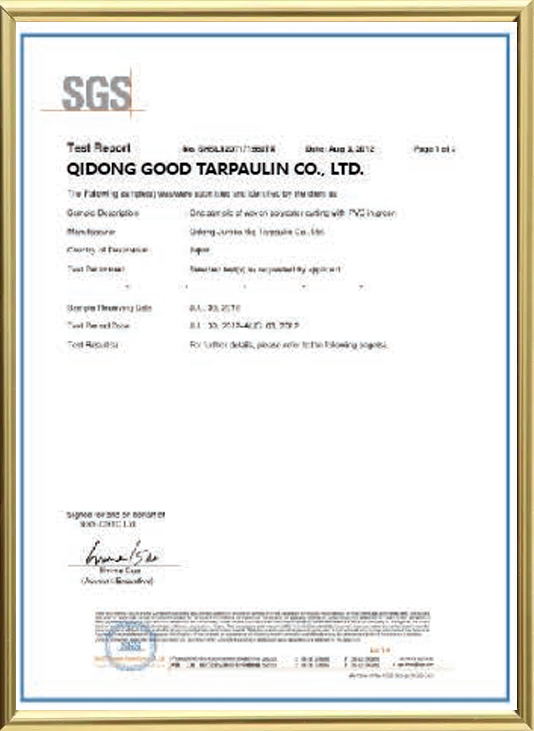

The last step is to "check qualifications and cases". heavy duty PVC tarpaulins produced by regular manufacturers will have corresponding quality inspection reports, marking key parameters such as tear resistance, tensile strength, and waterproof grade. You can ask the manufacturer to provide them. At the same time, you can check whether the manufacturer has cooperation cases related to "heavy-duty" scenarios, such as whether it has provided products to mines, ports, and heavy machinery companies. The richer the cases, the more guaranteed the product quality. As a professional manufacturer with more than 20 years of experience, Qidong Good Tarpaulin provides detailed quality inspection reports for its heavy duty PVC tarpaulins, and has many cooperation cases in the fields of mining, logistics, and heavy machinery. The product quality has been verified by the long-term market, allowing users to choose with confidence.