In the selection of PVC tarpaulin, "D" (denier, representing fiber thickness and fabric density) is a key indicator for judging product strength and applicable scenarios. 500D, 840D, 1000D, and 1300D are commonly used specifications on the market. However, many users do not know the core differences between different "D" values, nor do they know how to match them according to their own needs. This article will help everyone clarify the characteristics and application logic of different specifications by answering key questions and combining them with corporate practice.

1. What performance differences will the differences in “D value” of 500D, 840D, 1000D and 1300D PVC tarpaulin bring?

When many users see signs such as "500D" and "1300D", they only know that the larger the number, the more durable it may be, but they lack a clear understanding of the specific performance differences. In fact, the "D value" represents the fiber weight (grams) per 9000 meters of length. The higher the D value, the thicker the fiber, and the denser the woven base fabric, which in turn brings three core performance differences:

One is tear resistance and tensile strength: the higher the D value, the stronger the fabric's ability to resist external tearing and stretching. For example, the tear resistance of 500D PVC tarpaulin is about 250-350N, which is suitable for light pulling scenarios; while the tear resistance of 1300D PVC tarpaulin can reach 600-800N, which can withstand the friction and strong pulling force of heavy goods. For example, in scenes such as covering sharp ores in mining transportation, specifications above 1000D are needed to avoid damage.

The second is wear resistance: the higher the D value, the better the wear resistance of the fibers on the surface of the fabric. 840D PVC tarpaulin is suitable for medium-frequency friction scenarios, such as outdoor camping tents and short-distance transportation coverings for ordinary trucks; while the wear resistance of 1000D and 1300D PVC tarpaulin can be increased by more than 50%, making it suitable for long-term repeated use scenarios, such as container tarpaulins that are frequently loaded and unloaded in logistics parks, or heavy machinery protective covers that are parked outdoors all year round.

The third is weight and thickness: the higher the D value, the weight and thickness of the fabric will also increase accordingly. 500D PVC tarpaulin weighs about 400-500 grams per square meter and has a thickness of about 0.3-0.4mm. It is light and easy to store and is suitable for scenes that require frequent transportation. 1300D PVC tarpaulin weighs up to 800-1000 grams per square meter and has a thickness of 0.8-1.0mm. Although it is heavier, it is more protective and is suitable for long-term covering of fixed scenes.

When Qidong Good Tarpaulin Co., Ltd. produces PVC tarpaulins with different D values, the process is optimized based on the D value characteristics: for example, when producing 500D tarpaulin, a lightweight base fabric is used with a thin coating to ensure portability; when producing 1300D tarpaulin, a high-strength polyester fiber base fabric is used, and a double-layer PVC coating is superimposed to further enhance the wear resistance and tear resistance, ensuring that products with different D values can match the needs of corresponding scenarios.

2. Faced with four D value specifications, how to choose accurately in different scenarios to avoid "choosing expensive but not right" or "choosing light but not durable"?

Many users tend to fall into two misunderstandings when choosing: either they think "the higher the D value, the better" and blindly choose 1300D, resulting in a waste of costs; or they choose 500D to save costs, resulting in frequent replacement due to insufficient wear resistance. In fact, the D value needs to be matched according to the three dimensions of "scene stress intensity", "frequency of use" and "portability requirements":

500D PVC tarpaulin: suitable for light protection, high-frequency portable scenarios, such as outdoor drying covers for families, small camping tents, and short-distance transportation of lightweight goods (such as clothing, small appliances). In this type of scenario, the external friction is small and the use time is short. The portability and basic protective performance of 500D are completely sufficient. If you choose a higher D value, it will increase the difficulty of transportation.

840D PVC tarpaulin: suitable for medium-strength, conventional and durable scenarios, such as medium and long-distance transportation by ordinary trucks (the goods are furniture and daily necessities), outdoor temporary storage (such as short-term storage of building materials and agricultural products), and outdoor awnings in scenic spots. Such scenes require a balance between durability and ease of operation. The tear resistance and wear resistance of 840D can handle normal friction, and the weight is not too heavy, making it easy to cover and store manually.

1000D PVC tarpaulin: suitable for medium-to-heavy protection and long-term use scenarios, such as heavy trucks transporting steel, pipes and other goods, short-distance transport of ore in mines, or temporary protective covers for large outdoor equipment (such as excavators, generators). In this type of scenario, the cargo is heavy and has strong friction. The strength of 1000D can prevent the tarpaulin from tearing due to bumps during transportation. At the same time, it is lighter than 1300D, taking into account both protection and operational efficiency.

1300D PVC tarpaulin: suitable for heavy-duty protection and extreme environmental scenarios, such as long-term stacking and covering of port containers (need to withstand the pressure of the upper container), long-distance transportation of large ores in mines (sharp edges and strong friction), and protective covers for large outdoor storage tanks in oil fields (long-term withstand the impact of strong winds and heavy rains). This type of scene requires extremely high strength and durability. The high tear resistance and wear resistance of 1300D meet the needs of long-term use and reduce the frequency of replacement.

Qidong Good Tarpaulin will accurately recommend D values based on customer scenarios: for example, it recommends 500D tarpaulin for camping equipment manufacturers to make portable tents; it recommends 1000D and 1300D tarpaulin for heavy logistics companies to make truck covers and container tarpaulins, which not only ensures the protective effect but also avoids cost redundancy.

3. When customizing PVC tarpaulins with different D values, in addition to confirming the D value, what other parameters are needed to ensure that it fits the scene?

Some users only specify “840D” or “1000D” when customizing, but ignore other key parameters, resulting in a mismatch between the finished product and the scene. In fact, the D value is the basis and needs to be customized in combination with three core parameters:

The first is coating type and thickness: oilcloths with different D values need to be matched with corresponding coatings to maximize performance. For example, if 500D tarpaulin is used for outdoor camping, it needs to be matched with a light and environmentally friendly PVC coating to ensure waterproofness while reducing weight; if 1300D tarpaulin is used to cover a chemical industry park, it needs to be equipped with an anti-corrosion PVC coating to prevent chemical gases from corroding the fabric. Qidong Good Tarpaulin will adjust the coating thickness according to the D value and the scene: the thickness of the 500D tarpaulin coating is about 0.1-0.2mm, and the thickness of the 1300D tarpaulin coating can reach 0.3-0.4mm to enhance protection.

The second is the waterproof level: different D value tarpaulins have different waterproofing requirements, and the waterproof standards of the scene need to be clearly defined. For example, 840D tarpaulin is used for general warehousing, and the waterproof level must reach "moderate rain resistance" (hydraulic pressure test ≥ 1500mm); 1000D tarpaulin is used for outdoor heavy machinery protection, and must reach the "heavy rain resistance" level (hydraulic pressure test ≥ 3000mm) to prevent rainwater from penetrating and damaging equipment.

The third is accessories and reinforcement methods: different D values mean different accessories and reinforcement processes. Because of its light weight, 500D oilcloth can be equipped with plastic buckles and light ropes for easy disassembly; because of its high stress, 1300D oilcloth needs to be equipped with high-strength metal buckles and thickened reinforcing ropes, and double-stitched + metal reinforcement sheets are used at the corners to prevent stress points from cracking. For example, when Qidong Good Tarpaulin customizes the 1300D container tarpaulin, it will add a 5cm×5cm double-layer base fabric reinforcement to each metal buckle to ensure that it will not tear during hoisting.

4. How to judge whether the PVC tarpaulins marked with "500D/840D" and other specifications on the market really meet the corresponding D value standards?

There are situations in the market where some manufacturers falsely mark the D value. For example, 840D tarpaulin is marked as 1000D, resulting in substandard performance when users actually use it. Ordinary users can identify through three methods: "see, test, and check":

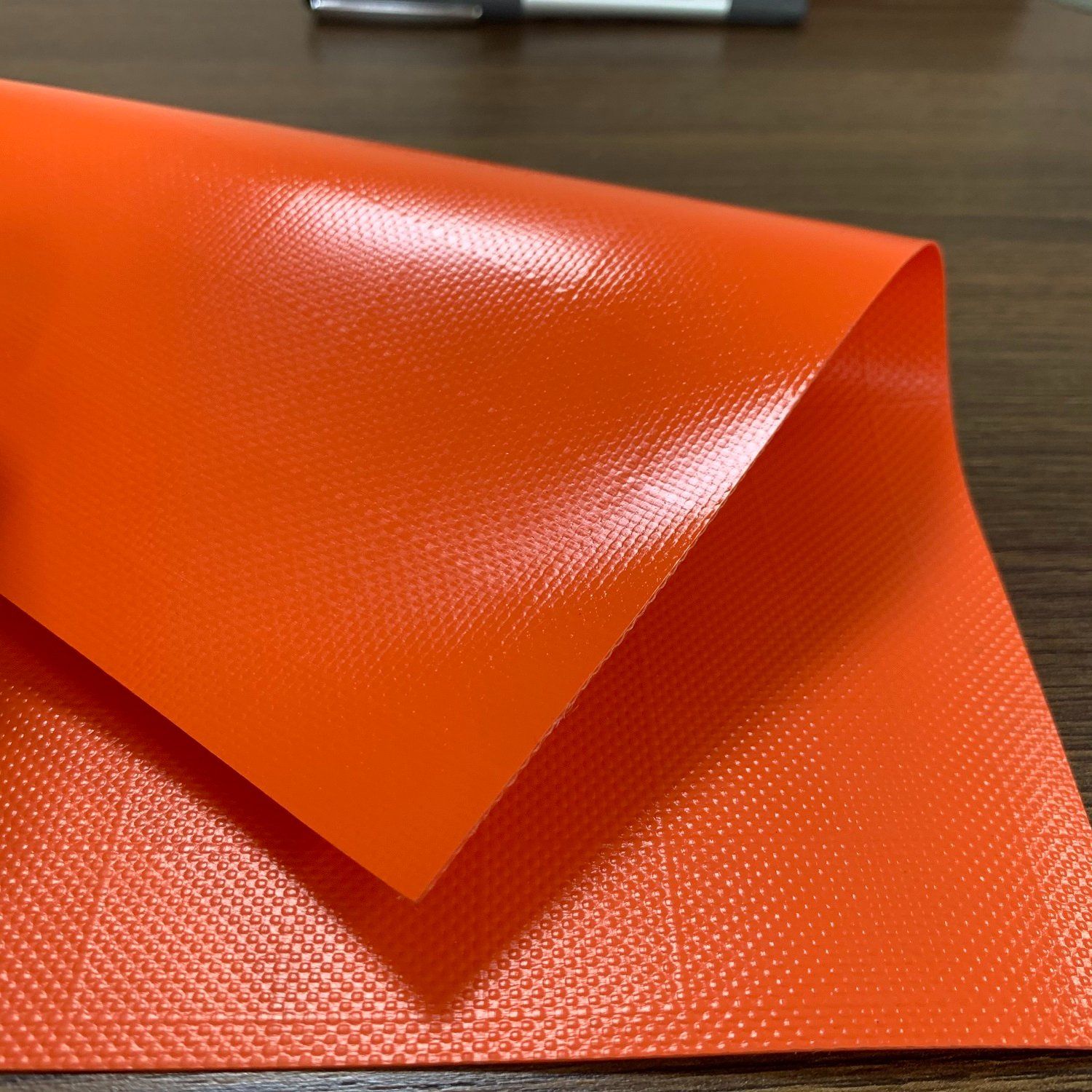

Look at the fabric details: the base fabric of high-quality 500D PVC oilcloth has a sparse texture and slightly better light transmittance; the base fabric of 1300D oilcloth has a tight texture, is almost opaque, and has a thicker surface feel. At the same time, observe whether the coating is uniform. If there is local uneven thickness, it may be cutting corners, which will affect the performance corresponding to the D value.

Simple weight test: According to the corresponding relationship between D value and weight, it can be roughly judged: Take a 10cm×10cm oilcloth sample, the 500D sample weighs about 4-5 grams, the 840D weighs about 7-8 grams, the 1000D weighs about 9-10 grams, and the 1300D weighs about 12-13 grams (including coating). If the sample weight is significantly lower than the corresponding range, there may be a false D value.

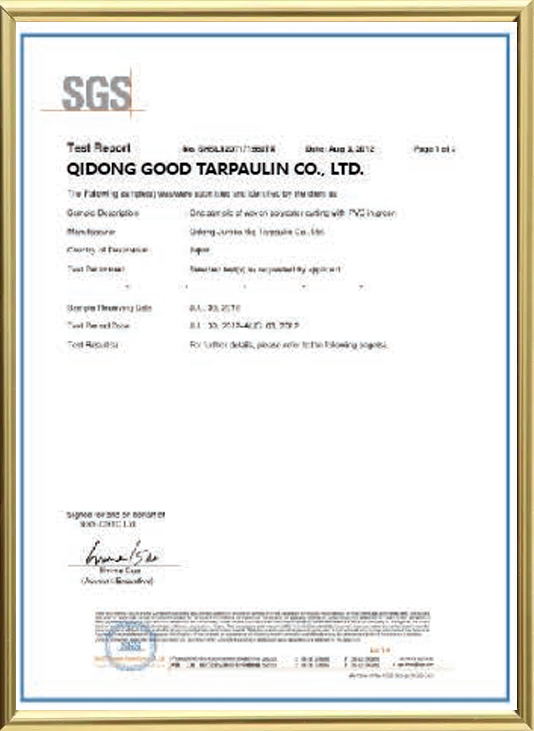

Check the test report and manufacturer qualifications: Regular manufacturers will provide test reports corresponding to the D value, marking the base fabric fiber specifications, tear strength and other parameters. For example, each batch of oilcloths with different D values produced by Qidong Good Tarpaulin comes with a third-party test report to clarify the performance indicators corresponding to the D value. At the same time, choose manufacturers with more than 20 years of production experience (such as Qidong Good Tarpaulin), whose production processes are more mature and the probability of false standards is lower.