I. The core performance of PVC Tarp: Why has it become the mainstream protection choice?

PVC Tarp is made of polyester or nylon fiber as the base fabric and coated with polyvinyl chloride resin. Its performance advantages come from the synergy between the base fabric and the coating. It can be summarized as the following four points, which are also its core competitiveness that distinguishes it from PE Tarp and traditional canvas:

1. Super waterproof, able to cope with complex humid environments

The coating of PVC Tarp is dense and has strong adhesion, which can form a complete waterproof barrier. The waterproof level can reach more than 1500mm water column (that is, it can withstand the pressure of 1.5 meters high water column without leakage). Whether it is heavy rain, melting snow or humid fog, it can effectively block moisture penetration. Even the finished PVC Tarp sewn by splicing can maintain good waterproofness at the seams through heat sealing or waterproof tape treatment, avoiding water leakage problems caused by traditional needle and thread stitching. This characteristic makes it particularly suitable for outdoor cargo covering, truck transportation, outdoor equipment protection and other scenarios. For example, when transporting food and electronic products in the rainy season, it can effectively prevent the goods from getting damp and mildewed.

2. Excellent weather resistance, adaptable to various climate conditions

High-quality PVC Tarp will be added with anti-UV agents, anti-aging agents and other functional additives during the production process, which can resist the erosion of ultraviolet rays, high and low temperatures, wind and rain and other natural factors. Its applicable temperature range is usually - 20℃ to 60℃. It is not easy to become hard and brittle when used in cold areas in winter. It is not easy to soften and deform when exposed to the sun in high temperature areas in summer. Its outdoor service life can reach 5-8 years. In contrast, PE Tarp is prone to aging and cracking due to long-term outdoor use, while traditional canvas requires frequent maintenance to maintain weather resistance. The "maintenance-free" feature of PVC Tarp significantly reduces long-term use costs.

3. High tear resistance, suitable for high-frequency use

The base fabric of PVC tarp is mostly made of high-density polyester or nylon. Combined with the reinforcement effect of PVC coating, the tear resistance and wear resistance are far superior to other types of tarps. After testing, the warp and weft tear strength of high-quality PVC Tarp are both ≥200N. It can withstand the pulling force caused by cargo handling and vehicle bumps, and is not easily damaged even if it is slightly scratched. For example, truck tarps that frequently load and unload goods in logistics parks, or protective covers covering large industrial equipment, PVC Tarp can withstand friction and pull for a long time, reducing the frequency of replacement due to damage.

4. Good plasticity to meet customized needs

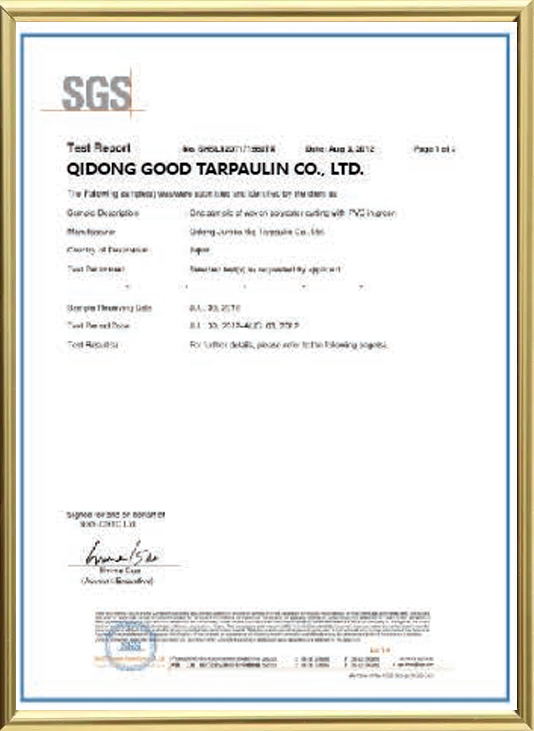

PVC Tarp has strong processing adaptability. By adjusting the base fabric density, coating thickness, and adding functional additives (such as flame retardants, anti-static agents), it can achieve special properties such as flame retardancy, anti-static, and acid and alkali resistance. At the same time, it is easy to cut and sew, and can be processed into finished products of different sizes and structures according to specific needs, such as truck covers, container tarps, machine protective covers, outdoor tents, etc. Professional manufacturers such as Qidong Good Tarpaulin can customize full-process solutions from basic fabrics to finished products according to customer scene needs, such as customizing acid and alkali-resistant PVC Tarp for chemical companies, and customizing flame-retardant PVC Tarp that meets environmental protection standards for European customers, adapting to more niche scenarios.

II. How to choose PVC Tarp? 4 steps to avoid misunderstandings and choose the right product

Model selection is the key to exerting the protective effect of PVC Tarp. If you choose blindly, problems such as "excessive performance and waste of cost" or "insufficient performance and frequent replacement" may occur. The following 4 steps can help users accurately match their needs and improve procurement cost-effectiveness:

1. Clarify usage scenarios and lock in core requirements

Different scenarios have significantly different performance requirements for PVC Tarp. Before selecting, you need to sort out 3 key information:

Usage environment: outdoor or indoor? Have you been exposed to ultraviolet rays, rain, acid and alkali environments for a long time? For example, outdoor truck transportation needs to focus on "UV resistance + waterproofing", and chemical workshop equipment protection needs to focus on "acid and alkali corrosion resistance";

Protected object: Is the protected object afraid of moisture, sun, or scratches? What about weight and volume? For example, covering precision electronic equipment requires “dustproof + mild waterproofing”, and covering heavy machinery requires “high tear resistance + abrasion resistance”;

Frequency and period of use: short-term temporary use (such as 1-3 months) or long-term fixed protection (such as more than 3 years)? High frequency loading and unloading or static coverage? For short-term use, you can choose the regular thickness (0.4-0.5mm), and for long-term use, it is recommended to choose the thicker version (0.6-1.0mm).

If you are not clear about your needs, you can refer to the experience of professional manufacturers. For example, Qidong Good Tarpaulin has more than 20 years of experience in PVC Tarp production. It can recommend suitable product parameters based on the scenarios described by customers (such as "Outdoor trucking in Southeast Asia, average annual rainfall of 1500mm"), and can also provide free samples for testing to avoid selection errors.

2. Pay attention to key parameters and judge product quality

Without professional testing equipment, you can initially judge the quality of PVC Tarp through the following 3 key parameters and simple methods:

Thickness and weight: For the same material, PVC Tarp, thickness and weight are usually positively related to durability. It is recommended to choose a thickness of 0.5-0.7mm for regular scenarios, and 0.8-1.0mm for long-term outdoor or heavy-duty protection. In terms of weight, for products with a weight of ≥500g per square meter, the density of the base fabric and the thickness of the coating are more secure;

Coating uniformity: The surface of high-quality PVC Tarp is smooth, and the coating has no bubbles, leaks, or impurities, and there is no obvious concave and convex feeling when touched by hand; inferior products may have uneven coating thickness, and even partially expose the texture of the base fabric, which is easy to be damaged from weak points;

Seam treatment: The finished PVC Tarp needs to pay attention to whether there are heat-sealed edges or waterproof strips at the seams. Rub the seams with your hands to see if there are no signs of glue opening or water seepage. If it is a basic fabric, you need to confirm the fit between the base fabric and the coating. Pull the fabric without the coating falling off.

3. Distinguish between good and bad quality and avoid the trap of inferior quality

Some inferior PVC Tarps on the market have the problem of "cutting corners", such as using low-density base fabric, thin coating, and recycled materials, resulting in a service life of only 1-2 years, which is much lower than the 5-8 years of high-quality products. When purchasing, you can use the three methods of "looking, touching and smelling" to identify:

Look: the high-quality PVC Tarp has uniform color and no obvious color difference; the base fabric has clear texture and no jumpers or broken wires; the coating has no scratches or missed coatings;

Touch: It feels thick and elastic, and can rebound quickly after being pressed; inferior products feel thin and brittle, or the coating has a sticky feel (excessive plasticizer may be added, which is prone to aging);

Smell: High-quality PVC Tarp has no pungent odor (such as strong plastic smell, sour smell); inferior products may have pungent odor due to the use of recycled materials or inferior additives, and long-term use may also release harmful substances, affecting the environment and health.

4. Choose “fabric” or “finished product” as needed, taking into account efficiency and cost

The purchasing form of PVC Tarp is divided into "basic fabric" and "finished product", which need to be selected according to their own processing capabilities and needs:

Select basic fabrics: If the company has cutting and sewing equipment and a team, it is more flexible to purchase basic fabrics and process them by itself, which is suitable for batch standardized products (such as uniform-size cargo covering cloth);

Select finished products: If you need special structures (such as non-standard size truck covers, equipment covers with access openings), or do not have processing capabilities, it is more efficient to purchase finished products directly. Professional manufacturers such as Qidong Good Tarpaulin can provide one-stop service from fabrics to finished products. According to customer drawings or size requirements, they can be processed into finished products with zippers, Velcro, and fixed rope holes. The factory direct supply model can reduce the cost of intermediate links, saving 15%-20% compared to "outsourced fabric + outsourced processing".

III. Scenario-based application of PVC Tarp: operating skills from theory to practice

The usage methods of PVC Tarp vary greatly in different scenarios. Correct operation can improve the protective effect and extend the service life. The following 4 practical skills for core scenarios can be directly applied:

1. Logistics and transportation scenarios (trucks, trailers, containers)

Logistics and transportation are the core application scenarios of PVC Tarp, focusing on solving the balance between "cargo protection" and "easy operation":

Covering skills: First clean up the sharp protrusions (such as metal corners, screws) on the surface of the carriage or cargo, and wrap the protrusions with a soft cloth to avoid scratching the PVC Tarp; spread the Tarp flat to ensure that the cargo is completely covered, with the corners drooping ≥30cm and without wrinkles (folds can easily accumulate water and cause leakage);

Fixing method: Use tightening straps or high-strength ropes to bind the edges of the Tarp to the fixed points of the carriage/container. The tightening force should be moderate (it is appropriate for the Tarp to have no obvious slack) to avoid excessive pulling that may cause the seams to crack. It is recommended to use the "cross binding method" at the corners, or use metal buckles for reinforcement to prevent loosening due to bumps and wind resistance during driving;

Special handling: When transporting fresh food, flowers and other goods that require ventilation, you can choose a finished Tarp with a PVC mesh window, or leave a 10-15cm gap on the side of the Tarp (away from the direction of rain) and cover it with mesh for both ventilation and rain protection; pay attention to winter transportation. PVC Tarp will harden at low temperatures, and you should be gentle when folding or pulling to avoid brittleness.

2. Industrial protection scenarios (machines and equipment, workshop warehousing)

In industrial scenarios, PVC Tarp is mainly used to protect equipment from dust, moisture, and corrosion. The use method needs to be adjusted according to the characteristics of the equipment:

Protection of large equipment: Give priority to "detachable" finished PVC Tarp. Design zipper or Velcro openings at the equipment access openings and heat dissipation vents to facilitate partial disassembly during maintenance without the need for complete removal; if the equipment has protruding parts (such as pipes and valves), special-shaped Tarps can be customized to ensure good fit and protection without dead corners;

Protection of precision equipment: Choose "low dust" PVC Tarp (the coating is denser and less likely to fall off). Avoid direct contact with the surface of the equipment when covering it. You can place a soft cloth between the Tarp and the equipment to prevent scratches. If the equipment is in a humid environment, you can place a moisture-proof agent inside the Tarp and replace it regularly to improve the moisture-proof effect.

Covering warehousing goods: When covering shelf goods, the Tarp needs to hang down to 10-20cm from the bottom of the shelf to prevent dust from entering from the bottom; when covering stacked goods, first lay a flat layer of cardboard or plastic film on the top of the goods, and then cover the Tarp to avoid scratching the Tarp at the edges of the goods and reduce the friction between the Tarp and the goods.

3. Agricultural production scenarios (crop coverage, breeding protection)

The demand for PVC Tarp in agricultural scenes is both “protection” and “practicability”. The following tips can improve the use effect:

Crop covering: When anti-freezing in winter, choose thickened PVC Tarp (0.8-1.0mm), and compact the edges with soil or sandbags after covering to prevent cold wind from pouring in; when shading in summer, you can choose a composite version of PVC mesh and Tarp to take into account both shading and ventilation to avoid crop burns due to high temperatures; when covering a greenhouse, a soft cloth needs to be placed at the contact point between the Tarp and the scaffolding to reduce damage caused by friction.

Breeding protection: The PVC Tarp for livestock and poultry breeding sheds should be of the “easy to clean” type, with a smooth surface coating, making it easy to wash away feces and stains with clean water; for aquaculture rainproof sheds, it is necessary to ensure smooth drainage of the Tarp, and an inclination angle (5-10°) can be designed at the top to avoid water accumulation from collapsing the shed; PVC Tarps in breeding areas need to be inspected regularly to prevent damage caused by pecks by rats and birds.

4. Temporary outdoor scenes (camping, emergency rescue, temporary sunshade)

PVC Tarp for temporary outdoor scenes needs to take into account both "protection" and "portability". When using it, you need to pay attention to:

Camping and shading: When setting up a temporary tent or awning, choose a lightweight PVC Tarp (0.4-0.5mm) and match it with a stable bracket. The connection points between the bracket and the Tarp are tied with ropes to avoid displacement caused by strong winds; if the ground is wet, a waterproof floor covering can be laid at the bottom of the Tarp to improve the moisture-proof effect;

Emergency rescue: For emergency shelter, you need to choose PVC Tarp that is “easy to unfold”, and give priority to finished products (such as square Tarp with fixed ropes). After unfolding, use stones and sandbags to fix the edges to quickly build a temporary protective space; for night use, you can choose PVC Tarp with reflective strips to improve safety;

Storage after use: After outdoor use, you need to clean the sand and leaves on the surface of the Tarp first, rinse it with clean water and dry it, then fold or roll it up for storage to avoid the growth of mold in a humid environment.

IV. Maintenance and maintenance of PVC Tarp: 3 steps to extend service life

Proper maintenance can extend the service life of PVC Tarp by 2-3 years and reduce repeated purchase costs. The following 3 core maintenance steps are simple and easy to operate, suitable for individual and corporate users:

1. Daily use: avoid damage and reduce loss

Anti-scratch and pull: When covering or transporting, avoid direct contact between Tarp and sharp objects (such as metal corners, stones); when fixing, tighten the rope moderately, not exceeding the tensile limit of Tarp; if encountering strong wind, do not forcefully pull and fix it, you can temporarily loosen part of the rope to reduce damage to Tarp due to wind resistance.

Protection against high temperatures and fire sources: PVC material is not resistant to high temperatures and needs to be kept away from high-temperature objects such as heaters, stoves, and car exhaust pipes (distance ≥ 1 meter); it is prohibited to smoke or use open flames near the Tarp to prevent the Tarp from melting or burning;

Clean foreign objects in time: When foreign objects such as branches, stones, snow, etc. accumulate on the surface of the Tarp, they need to be cleaned in time to avoid the pressure of foreign objects causing the Tarp to deform, or the snow to melt and penetrate (if there is minor damage).

2. Regular cleaning: Protect coating and maintain performance

The coating of PVC Tarp is the core of protection. Avoid damaging the coating when cleaning:

Cleaning frequency: It is recommended to clean once every 1-2 months for outdoor use and every 3-6 months for indoor use; if there are corrosive stains such as oil, bird droppings, etc. on the surface, they need to be cleaned in time to avoid corrosion of the coating;

Cleaning method: Use clean water and a soft-bristled brush to gently scrub. Do not use strong acid or alkali cleaners (such as washing powder, dishwashing liquid), and do not use a high-pressure water gun to directly rinse the coating (it may cause the coating to fall off); oil stains can be wiped with a dry cloth first, and then rinsed with clean water;

Drying treatment: After cleaning, do not expose it to the sun (accelerates aging), place it in a ventilated and cool place to dry naturally, and wait until the Tarp is completely dry before folding or using it to avoid moisture causing the coating to become moldy.

3. Storage management: Moisture-proof and dust-proof to avoid aging

The storage method when not in use directly affects the next use effect of PVC Tarp:

Storage environment: Choose a dry, ventilated place without direct sunlight (such as warehouse shelves, indoor corners) to avoid moisture(Prevent mold), high temperature (accelerate aging), direct sunlight (fading and embrittlement);

Folding and placement: Avoid squeezing when folding, and store it in the manner of "first folding in half, then rolling into a tube" to reduce creases (long-term folding can easily cause the coating at the creases to age); when storing, keep away from sharp objects (such as tools, metal racks) to prevent scratches;

Regular inspection: When stored for a long time (more than 3 months), it needs to be taken out and inspected once a month to check whether there is mold or coating peeling. If problems are found, clean and repair them in time to avoid further damage.