1. Get to know PVC Barrier Safety Fencing Mesh: a safety protection material that is more than just “isolation”

PVC Barrier Safety Fencing Mesh is not a simple “mesh barrier”, but a functional protection product designed for the safety needs of different scenarios. Its core composition adopts a "substrate + coating" composite process: the substrate is made of high-tenacity polyethylene (PE) or polyester fiber, and the basic mesh structure is formed through plain weave, twill or diamond weaving processes to ensure the flatness and stretch resistance of the mesh surface; the surface PVC coating is attached through dip coating, spray coating and other processes. In addition to conventional weather resistance and anti-corrosion properties, some high-end products will also add special additives such as antistatic and flame retardant to expand application scenarios.

Compared with traditional protective materials, its core advantage lies in "scenario adaptability": for temporary protection in building construction, it can be designed into a high-density mesh to prevent small objects from falling; for municipal road warnings, it can be designed with high-visibility warning colors and reflective strips; for home pet protection, the mesh surface can be soft and burr-free. This "one material has many functions" characteristics makes it gradually replace traditional metal mesh and ordinary plastic mesh in the field of safety protection and become the mainstream choice.

2. Correspondence between core specifications parameters and characteristics of PVC Barrier Safety Fencing Mesh

When purchasing, you need to judge whether the product is suitable for the use scenario through the specification parameters. The corresponding relationship between the key parameters and features is as follows:

Mesh size (5mm-50mm): The smaller the mesh, the higher the protection accuracy - for example, 5-10mm mesh is suitable for child protection on balconies and equipment parts to prevent falling; 20-30mm mesh is suitable for construction enclosures and storage partitions; 40-50mm mesh is suitable for agricultural planting isolation and peripheral protection of large equipment, taking into account both protection and ventilation needs.

Wire diameter (1.2mm-4.0mm): The thicker the wire diameter, the stronger the impact resistance - 1.2-2.0mm wire diameter is suitable for low-impact scenarios such as homes and scenic spots; 2.5-3.0mm wire diameter is suitable for medium-impact scenarios such as municipal roads and industrial workshops; 3.5-4.0mm wire diameter is suitable for high-impact scenarios such as building high-altitude protection and heavy equipment isolation.

Width (1m-5m): Width selection needs to be combined with installation efficiency and scene size - 1-2m width is suitable for small irregular areas (such as elevator wellheads, equipment corners); 3-5m width is suitable for large-area continuous protection (such as construction site enclosures, road maintenance isolation), reducing splicing gaps and improving protection.

Coating thickness (0.1mm-0.5mm): Coating thickness directly affects weather resistance - 0.1-0.2mm coating is suitable for indoor scenes (such as workshop isolation); 0.3-0.4mm coating is suitable for general outdoor scenes (such as courtyard fences, scenic area separation); 0.5mm and above coatings are suitable for extreme environments (such as high altitudes, coastal humid areas), and the service life can be extended to more than 5 years.

Special performance parameters: Flame-retardant products must comply with GB 8624-2012 B1 level standard, with an oxygen index of ≥32%; antistatic products must have a surface resistance of ≤10^9Ω, which is suitable for flammable and explosive scenes such as chemical industry, oil and gas; reflective products must have a retroreflection coefficient of reflective strips of ≥30cd/(lx·m²) to ensure road warning visibility at night.

3. Scenario selection: How to choose the right PVC protective isolation net in different fields?

Building construction scene selection

Temporary fencing: Priority is given to yellow and black/red and white warning color products with a width of 3-4m, a mesh of 20-30mm, and a wire diameter of 2.5-3.0mm, with reinforced columns to ensure wind resistance (needs to be able to withstand wind force ≥8);

High-altitude protective net: Choose a high-density mesh with a mesh size of 10-15mm and a wire diameter of 3.0-3.5mm. The coating thickness is ≥0.4mm and must pass the anti-fall test (can withstand a 5kg weight dropped from a height of 3m without breakage);

Elevator wellhead isolation: Choose a product with a mesh size of 5-10mm and a width of 1.5-2m. The edges must have hooks or buckles to facilitate fixation with the wellhead frame, and the mesh surface must have a "No Climbing" warning sign.

Municipal and road scene selection

Road maintenance fence: Choose reflective products. 20cm wide reflective strips are set every 1m on the mesh surface. The mesh is 25-30mm and the wire diameter is 2.5mm. It is equipped with lightweight movable columns for quick disassembly and assembly;

Temporary warning of accidents: Choose a portable roll net with a width of 1-2m and a weight of ≤0.5kg/㎡. It can be folded and stored and is waterproof (no coating will fall off after being exposed to rain for 24 hours), which is suitable for emergency carry;

Isolation for pipeline maintenance: Choose anti-corrosion products, add anti-acid and alkali additives to the coating, mesh 30-40mm, wire diameter 2.0mm, to avoid soil corrosion of the mesh material during underground pipeline maintenance.

Home and agricultural scene selection

Balcony protection: Choose a soft mesh with a mesh size of 5-8mm and a wire diameter of 1.5-2.0mm. The edges have no burrs and can be fixed with Velcro or expansion screws to avoid scratching children;

Pet fence: For small and medium-sized pets (such as cats and small dogs), choose products with mesh openings of 10-15mm and wire diameters of 1.2-1.5mm. For large pets (such as golden retrievers and German shepherds), choose products with mesh openings of 20mm and wire diameter 2.0mm to ensure that pets cannot bite through or escape;

Agricultural planting isolation: Choose a light-transmitting product with a mesh of 30-50mm, a wire diameter of 1.5-2.0mm, and a coating thickness of 0.2-0.3mm. It takes into account the needs of insect control and crop lighting, and must be able to withstand pesticide spraying without coating damage.

4. Practical upgrades: installation skills and life extension strategies

Efficient installation tips

Large-area outdoor installation: First cut the mesh according to the size of the site, leaving a 5-10cm expansion margin (to avoid temperature changes causing the mesh to shrink and crack). The distance between the columns is controlled at 2-3m. The mesh and the columns are connected using "double buckle fixation", with 1 buckle at the top and bottom to prevent the mesh from loosening;

Installation in irregular areas: When encountering corners or curved areas, you can cut the mesh along the fold line, overlap it by 5-8cm, then paste it with PVC special glue, and then sew and reinforce it with nylon thread to ensure that there is no gap in the splicing;

Temporary emergency installation: carry portable hooks and elastic ropes, unfold the mesh and fix it on surrounding fixtures (such as trees, street light poles) with hooks. The elastic ropes can be adjusted for tightness, which is suitable for quick warning at the accident site.

Life extension strategies

Regular inspection: Outdoor products should be inspected every 3 months, focusing on whether the coating is peeling off, whether the mesh is deformed, whether the accessories are loose, and if any problems are found, repair them in time;

Seasonal maintenance: After high temperatures in summer, rinse the mesh surface with clean water to remove dust and oil to prevent dirt from accelerating the aging of the coating under high temperatures; after rain and snow in winter, clean the snow on the mesh in time to prevent the mesh from deforming due to snow pressure;

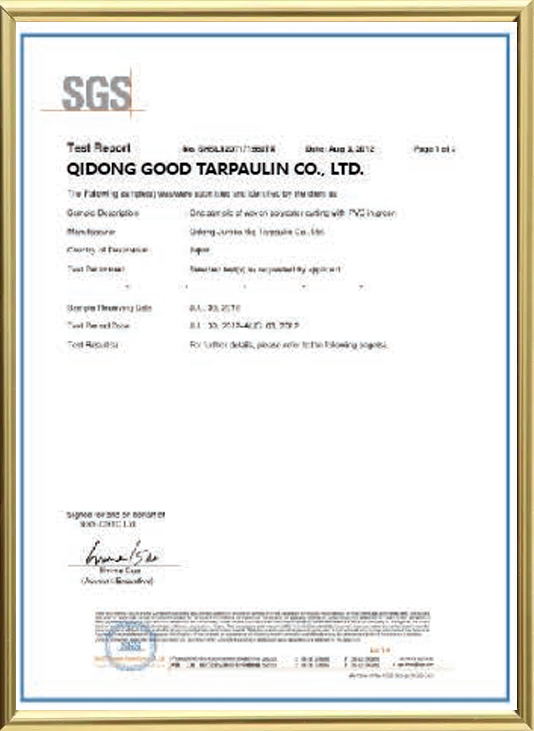

Storage optimization: When not in use for a long time, clean and dry the mesh and store it in rolls. Insert a plastic core with a diameter of 10cm in the middle to avoid folding and indentation. The storage environment temperature should be controlled at 5-30°C, and the relative humidity should be ≤60%. Professional manufacturers like Qidong Good Tarpaulin are particularly attentive to product details and user experience. They not only provide high-quality PVC protective isolation nets that meet industry standards, but also help users better maintain products and extend service life through professional usage guidance, demonstrating their deep concern for user needs and high-quality service capabilities.