1. What are the unique advantages of PVC Mesh Fabric compared with ordinary mesh fabric?

Although ordinary mesh (such as nylon mesh and polyester mesh) is breathable, it has obvious shortcomings in waterproofing, anti-aging, weather resistance, etc., making it difficult to adapt to complex environments. PVC Mesh Fabric achieves the combination of "mesh structure" and "PVC coating" through special processes. In what dimensions are its advantages reflected? First of all, the PVC coating gives the material excellent waterproofness and corrosion resistance. Even if it is used in rain, acid and alkali environments, it can avoid mildew and aging of the material, which is impossible for ordinary mesh fabrics. Secondly, the mesh structure can be customized according to needs, which can not only ensure air circulation, but also block dust and debris, taking into account both "breathability" and "protection". In addition, the tensile strength of PVC Mesh Fabric is much higher than that of ordinary mesh fabrics, which is not easy to deform and tear, and its service life can be 3-5 times that of ordinary mesh fabrics.

As a professional PVC fabric manufacturer in Qidong, the PVC Mesh Fabric produced by Qidong Good Tarpaulin has been further optimized in terms of process - by adjusting the weaving density of the base fabric and the thickness of the PVC coating, the product can greatly improve its UV resistance while maintaining breathability, and can reduce fading and embrittlement problems even if it is exposed to the sun for a long time. This characteristic makes it outstanding in scenes such as outdoor awnings and pet doors (taking into account both ventilation and protection), and is better suited to long-term outdoor use than ordinary mesh.

2. PVC Mesh Fabric has various mesh specifications. How to choose the appropriate specifications for different scenarios?

One of the core differences of PVC Mesh Fabric lies in the mesh specifications (such as 1mm×1mm, 5mm×5mm, 10mm×10mm, etc.). Are there clear boundaries for the application scenarios corresponding to different mesh sizes? The answer needs to be comprehensively judged based on the "purpose of use" and "protection requirements". For example, in industrial equipment protection scenarios, if you need to prevent dust and debris from entering the equipment, you need to choose PVC Mesh Fabric with smaller meshes (such as 1-3mm) while ensuring the sealing of the PVC coating. This type of product from Qidong Good Tarpaulin is often used in machine protective covers, which can prevent impurities from intruding and dissipate heat through the mesh to avoid equipment overheating. In outdoor sunshade scenarios (such as awnings, tent side curtains), you need to choose larger meshes (such as side curtains of tents). 5-10mm) products to ensure air circulation, while the PVC coating can block ultraviolet rays and provide a comfortable sunshade effect for the scene.

In addition, the shape of the mesh (square, diamond) will also affect the performance - the square mesh has a more uniform tensile strength and is suitable for scenes that require load-bearing (such as cargo isolation nets); the diamond mesh has better elasticity and is suitable for scenes that require bending (such as folding sunshades). Qidong Good Tarpaulin can customize PVC Mesh Fabric with different mesh specifications and shapes according to customer scene needs. The entire process from raw material weaving to coating processing can be controlled to ensure that the product accurately matches the actual application.

3. PVC Mesh Fabric needs to take into account both “breathability” and “durability”. How to judge whether its quality meets the standard?

Some PVC Mesh Fabrics on the market have problems such as "mesh clogging", "coating peeling off" and "easy to tear". How can ordinary users quickly identify the quality? This can be achieved through "three looks and three tests": first, look at the uniformity of the mesh - high-quality products have consistent mesh sizes without deformation or clogging. Qidong Good Tarpaulin uses precision weaving equipment to ensure that the mesh error per meter of fabric does not exceed 0.1mm; second, look at the coating adhesion - Use your fingernail to gently scratch the coating. If there is no peeling or wrinkling, it means that the coating and the base fabric are firmly combined. The company's products have passed the peel strength test and the coating adhesion can reach ≥5N/25mm, far exceeding the industry average. Thirdly, look at the edge flatness - there are no burrs or snags on the cutting edge, which represents the production process specification and can reduce subsequent processing losses.

The testing process can focus on two points: one is the air permeability test - use a hair dryer to blow on one side of the fabric, and you can feel uniform airflow on the other side, indicating that the air permeability meets the standard; the other is the weather resistance test - place the sample in the sun for 3-5 days, and the high-quality PVC Mesh Fabric has no obvious fading or hardening. The company's products add anti-UV agents, and the tensile strength retention rate after ultraviolet irradiation is ≥85%, ensuring the stability of long-term outdoor use. At the same time, Qidong Good Tarpaulin provides free sample services so that customers can verify product quality through actual testing and reduce procurement risks.

4. PVC Mesh Fabric has various customization scenarios for finished products. How to ensure the suitability of “fabric + processing”?

Many users not only need PVC Mesh Fabric fabrics, but also need to process them into finished products (such as sunshades, pet doors, equipment protective nets). If the fabrics do not match the processing technology, problems such as "edge cracking" and "mesh deformation" are prone to occur. Can choosing a manufacturer with the integrated capabilities of “fabric production + finished product customization” solve this pain point?

Qidong Good Tarpaulin has rich experience in customizing finished products, and its advantage lies in the "deep adaptation of fabric characteristics and processing technology": for example, when making pet doors, it will choose PVC Mesh Fabric with moderate mesh (3-5mm) and good elasticity, and use heat sealing technology to splice it to avoid mesh damage caused by needlework; when making industrial equipment protective nets, it will use fabrics with small mesh and high tensile strength, and use metal buckles to reinforce the edges to increase the load-bearing capacity. In addition, as a direct supplier from the factory, the company can reversely adjust the fabric parameters according to the demand for finished products. If the customer needs low-temperature-resistant outdoor sunshades, antifreeze will be added to the PVC coating to ensure that the fabric remains flexible in a -20°C environment and avoids cracking.

In terms of delivery efficiency, relying on 4 calendering production lines and 6 composite coating production lines, Qidong Good Tarpaulin's PVC Mesh Fabric fabric has an annual production capacity of up to 3 million square meters, and can quickly respond to fabric needs for customized finished products. At the same time, the company is only an hour's drive from Shanghai, and finished products can be conveniently shipped around the world through Shanghai Port. Whether it is a small batch sample or a large batch order, the delivery cycle can be guaranteed and customers can shorten the project landing time.

5. Different countries have different environmental standards for PVC Mesh Fabric. How should we deal with it when exporting?

As global environmental awareness increases, regulations such as EU REACH and US CPSIA impose strict requirements on the content of harmful substances (such as phthalates) in PVC products. If PVC Mesh Fabric does not meet the standards of the target market, customs clearance may be blocked. How can manufacturers with export experience help customers avoid compliance risks?

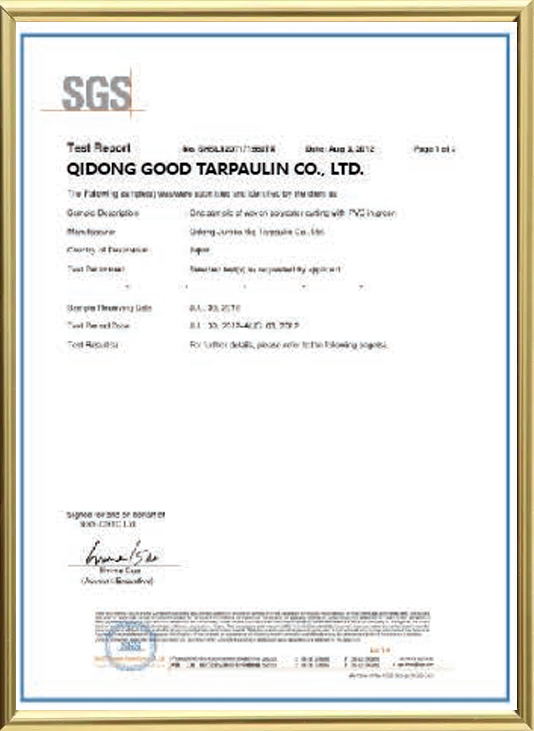

Qidong Good Tarpaulin's PVC Mesh Fabric has passed a number of international certifications, and its production process strictly controls the content of harmful substances - the phthalate content is ≤0.1%, in line with the EU REACH regulations; the content of heavy metals (lead, cadmium, etc.) is lower than the CPSIA limit, which can meet the needs of the US market. In addition, the company has been deeply involved in exporting for more than 20 years, and its products are exported to more than 90 countries and regions. It is familiar with the compliance details of different markets: for example, if European customers use protective nets in food processing workshops, they will provide additional food contact certification; if Southeast Asian customers use them for outdoor sunshade, they will optimize the anti-fungal performance of the fabric according to the local high temperature and high humidity environment. Customers only need to clarify the target market, and the company can provide PVC Mesh Fabric and related certification documents that comply with local standards to ensure a smooth export process.