1. What exactly is PVC Fabric? What are the core differences compared with other polymer fabrics?

Many users’ understanding of PVC Fabric only remains at the “plastic fabric” level, and its essential characteristics and applicable boundaries are still unclear. In fact, PVC Fabric is a functional fabric made of polyester or nylon and other fibers as a base fabric and compounded with PVC (polyvinyl chloride) resin through coating, calendering and other processes. It combines the toughness of the base fabric with the protective performance of PVC. Compared with PE (polyethylene) fabrics and PU (polyurethane) fabrics, what are its core differences?

From a performance point of view, PVC Fabric has better waterproofing and weather resistance - although PE fabric is lightweight, it is prone to aging and cracking after long-term outdoor use; PU fabric is soft to the touch, but is weak in acid and alkali corrosion resistance; and PVC Fabric can achieve a waterproof level of ≥1500mm water column and an anti-UV aging life of 5-8 years by adjusting the thickness and formula of the PVC coating. It can maintain stable performance even in high temperature, high humidity or acid-base environments. Qidong Good Tarpaulin is a professional manufacturer that has been in the industry for more than 20 years. The PVC Fabric it produces has been continuously optimized in the combination process of base fabric and coating, so that the product not only has sufficient tensile strength (warp tensile strength ≥ 300N/5cm), but also can flexibly adapt to the flexibility needs of different scenarios. This is the core reason why its products can cover PVC tarpaulin fabric, PVC mesh fabric, PVC canvas fabric and other categories.

2. PVC Fabric has various performance parameters. What specific application scenarios do different parameters correspond to?

When purchasing PVC Fabric, users often face many parameters such as "waterproof level", "tensile strength", and "flame retardant level". How do these parameters match the actual application scenario? Not all PVC Fabrics are universal, and core performance needs to be accurately selected based on scene requirements. For example, in logistics and transportation scenarios (such as truck covers, container tarps), "wear resistance, tear resistance" and "water resistance" are key - Qidong Good Tarpaulin's PVC Fabric for this scenario will use high-density polyester base fabric and thickened PVC coating to make the product wear-resistant for more than 5,000 times. At the same time, the heat-sealing edge sealing process is used to improve the waterproof sealing to ensure that the goods are protected from rain and dust during long-distance transportation.

In outdoor tent and awning scenarios, in addition to waterproofing, "UV resistance" and "breathability" (in some scenarios) are particularly important. The company's outdoor PVC Fabric will be added with a high-efficiency anti-UV agent, with a UV blocking rate of ≥90%, to prevent the fabric from fading and hardening after long-term exposure to the sun. The PVC mesh fabric used for tent side curtains has customized mesh specifications (5-10mm) to ensure anti-UV performance while achieving good air circulation and improving outdoor comfort.

In industrial equipment protection scenarios, "acid and alkali corrosion resistance" and "flame retardancy" have become core requirements. Qidong Good Tarpaulin can add corrosion-resistant agents or flame retardants to the PVC coating according to customer needs, so that the fabric can withstand acid and alkali environments with a pH value of 2-12, or meet the GB 8624-2012 B1 level flame retardant standard, providing safe and reliable protection for machinery and equipment, and reducing equipment failures and downtime caused by environmental factors.

3. There is an obvious quality gap among PVC Fabrics on the market. How to quickly identify the quality of products?

Faced with PVC Fabrics with widely varying prices and different qualities on the market, ordinary users lack professional testing equipment. How can they judge product quality through simple methods? You can start from three dimensions: "Appearance Observation", "Feeling and Touching" and "Simple Testing":

In appearance, high-quality PVC Fabric has a smooth surface, a uniform coating without bubbles, impurities or missing coatings, and a clear base fabric texture with no obvious jumpers or broken wires; inferior products may have problems such as uneven coating thickness and rough edges. Qidong Good Tarpaulin uses precision coating and calendering equipment, and the coating thickness error per meter of fabric is controlled within ±0.02mm to ensure stable product appearance and performance.

In terms of feel, high-quality PVC Fabric feels thick and elastic, and can rebound quickly after being pressed without a stiff feeling. If it feels thin, brittle, or the coating has a sticky feel, there may be problems with inferior material or unreasonable formula. The company's PVC Fabric optimizes the ratio of base fabric and coating so that the product maintains a certain hardness to resist deformation and is moderately flexible for easy processing.

In terms of simple tests, the waterproofness can be preliminarily judged through the "water dripping method" - pour water on the surface of the fabric. If the water droplets can roll off quickly without penetrating, the waterproofness meets the standard; the abrasion resistance can be passed through the "friction test" - rub the surface of the fabric repeatedly with a rough object 10-20 times. For high-quality products, no coating will fall off or the base fabric will be exposed. In addition, Qidong Good Tarpaulin provides free sample services so that customers can intuitively feel the product quality through physical testing. At the same time, the company is equipped with a professional quality inspection team and advanced testing equipment to test each batch of products for waterproof, tear resistance, weather resistance and other indicators to protect quality.

4. From basic fabrics to finished product customization, how to choose PVC Fabric’s customization services?

Many users not only need PVC Fabric basic fabrics, but also customize finished products according to specific application scenarios (such as truck covers, trailer covers, fruit picking bags, pet doors, etc.). What core points should be paid attention to when choosing customized services? First of all, it is necessary to choose a manufacturer with the ability to integrate "fabric production + finished product processing" to avoid finished product quality problems caused by mismatch between fabrics and processing technology.

Qidong Good Tarpaulin has a complete customization service system. Its advantage lies in "full control from fabric to finished product": for example, when customizing a truck cover, it will first recommend suitable PVC based on the size of the truck model and the use environment (such as whether it often travels in rainy and dusty areas). Fabric (such as thickened waterproof type, wear-resistant and tear-resistant type) is processed through professional cutting and heat sealing processes to ensure that the truck cover fits the car body without any hidden dangers of rain or dust leakage. When customizing fruit picking bags, lightweight and flexible PVC Fabric will be used, and reasonable openings and load-bearing structures are designed to facilitate picking operations and fruit storage.

Secondly, the “flexibility” and “delivery efficiency” of customization are also crucial. The company can quickly issue customized solutions based on the drawings, dimensions or samples provided by customers, and can respond flexibly whether it is a small batch sample customization (such as 10-20 pieces of pet doors) or a large batch order (such as 1000+ square meters of industrial equipment cover). Relying on 4 calendering production lines and 6 composite coating production lines, its annual PVC Fabric production capacity reaches 3 million square meters, which can quickly meet the fabric needs of customized finished products. At the same time, the company is only an hour's drive from Shanghai, and finished products can be easily shipped to the world through Shanghai Port, ensuring a controllable delivery cycle and helping customers shorten project implementation time.

5. PVC Fabric export faces different national regulatory requirements. How to ensure compliance?

With the development of international trade, PVC Fabric exports need to comply with the environmental protection and safety regulations of the target market, such as the EU REACH regulations, the US CPSIA standards, the Australian AS/NZS standards, etc. If the product does not meet the requirements, it will easily lead to blocked customs clearance and loss of orders. How to choose a manufacturer that can provide compliant products?

Qidong Good Tarpaulin has been engaged in exporting for more than 20 years, and its products are exported to more than 90 countries and regions. It is familiar with the regulatory details and compliance requirements of different markets: for the EU market, its PVC Fabric strictly controls the phthalate content ≤0.1%, complying with the restrictions of Appendix XVII of the REACH regulations; for the US market, the heavy metal (lead, cadmium) content of the product is lower than CPSIA 101 The limit value specified in Article 1 (lead ≤ 100 ppm); for the Southeast Asian market, taking into account the local high temperature and high humidity environment, the anti-fungal performance of the fabric will be optimized to ensure that the product meets local health standards.

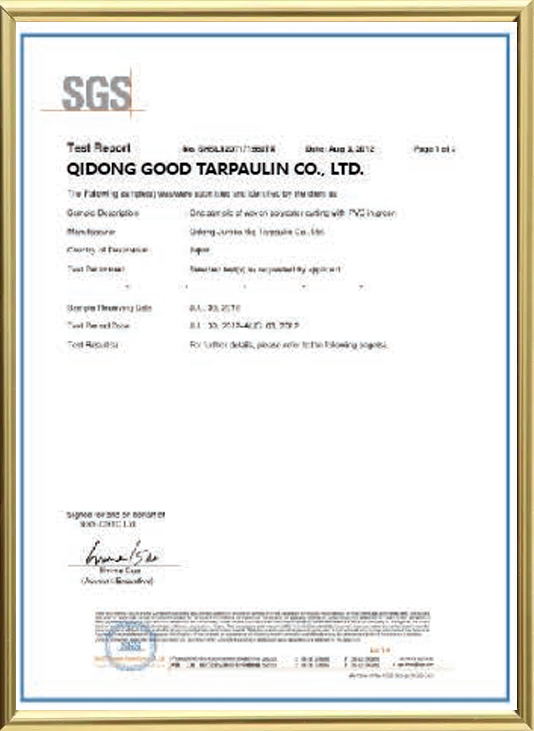

In addition, the company can provide relevant compliance certification documents based on customer needs, such as SGS test reports, REACH compliance statements, etc., to help customers successfully pass customs clearance. For example, when European customers purchase PVC curtains for food warehouses, the company can provide food contact grade test reports to prove that the products will not release harmful substances during use and ensure food safety. This in-depth understanding of global regulations and compliance capabilities have become an important support for its products to gain a foothold in the international market.