1. What are the “localization” requirements for the core properties of PVC canvas in the tropical climate of Malaysia and Thailand?

Malaysia and Thailand both have tropical climates, but their subdivided climate characteristics are different, which directly determines the performance focus of PVC canvas. Malaysia has high temperatures (daily average 25-32℃), rainy weather (annual precipitation 2000-3000mm) and high humidity (70%-90%) throughout the year. Coastal areas (such as Penang and Johor) are often affected by typhoons; Thailand has a rainy season (June-October, heavy rains are concentrated) and a dry season (November-May, high temperature and dryness, with sand and dust in some areas).

This climate difference has three core differences in the "localized" performance requirements of PVC canvas: First, the balance between waterproofing and moisture-proofing. In Malaysia's high-humidity environment, PVC canvas needs to be both "strongly waterproof" (to resist heavy rain) and "weakly breathable" (to avoid moldy condensation on the inside). For example, canvas used for temporary cover after oil palm harvesting, if moisture-proof is insufficient, can easily lead to oil palm fruit rot; although Thailand is rainy in the rainy season, it is dry in the dry season, so the moisture-proof requirements can be appropriately reduced and strengthened instead. "Resistant to UV aging" (to deal with strong sunlight in the dry season), such as rice covering canvas for outdoor storage, it is necessary to avoid exposure to the sun causing the coating to crack. The second is wind resistance and structural stability. During the typhoon season in Malaysia, outdoor canvases (such as port storage sheds and temporary tents) are required to have a wind resistance level of 10 or above, and stainless steel accessories are required for edge reinforcement (to prevent rain corrosion). In Thailand, except for the southern coast, the inland wind is weak, and the wind resistance requirement can be reduced to level 8. Galvanized materials are available for accessories to reduce costs. The third is temperature resistance and anti-adhesion. The high-temperature environments in both places require PVC canvas to have "high-temperature resistance and softening" properties (to avoid coating adhesion caused by high temperatures above 40°C). However, during the extreme high temperatures in Thailand during the dry season (up to 38-40°C), additional high-temperature stabilizers need to be added, such as the canvas used to transport durians by truck, to prevent fabric deformation caused by high temperatures.

2. What are the different preferences for the specifications of PVC canvas in the main industries (agriculture, logistics, manufacturing) of Malaysia and Thailand?

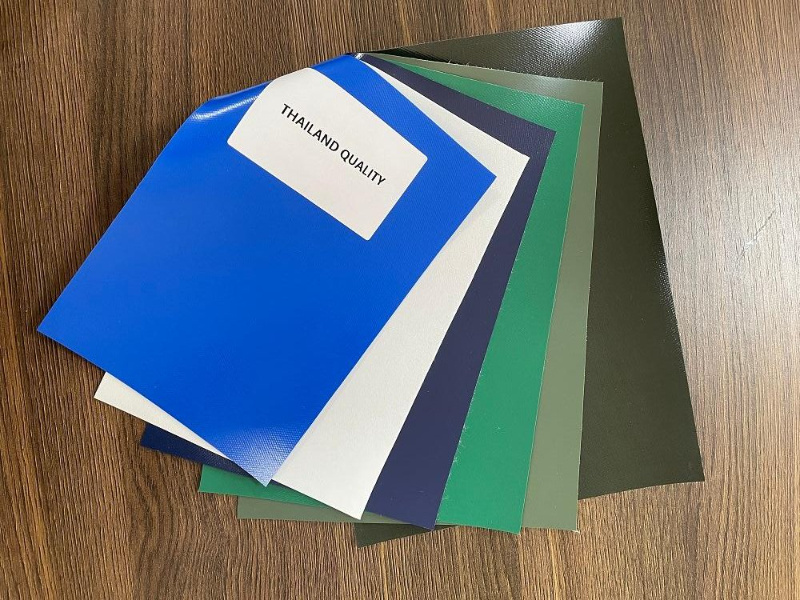

The differences in industrial structure between the two places have led to obvious preferences in the specification demand for PVC canvas. From an agricultural point of view, Malaysia mainly cultivates tropical cash crops (oil palm, rubber, cocoa), and PVC canvas is needed for: ① rain-proof cover after oil palm fruit picking (needs to be light and easy to carry, convenient for field operation); ② temporary storage shed in rubber plantations (needs to be light-transparent, easy to view rubber products). Therefore, I prefer 500D and 840D medium and low D value canvas. The color is usually light gray (both light transmittance and sun protection), and the fabric needs to be soft and easy to fold.

Thailand's agriculture is centered on the cultivation of rice and fruits (durian, mangosteen), and the demand is concentrated on: ① rainproof cloth for drying after rice harvesting (needs to be frequently unfolded/stored, required to be lightweight and durable); ② insulation cover for fruit transportation (requires composite thin insulation layer, combined with ice packs to maintain low temperature), so 840D medium D value canvas is the most popular, and some products require customized insulation structures. From the perspective of logistics scenarios, Malaysia, as a logistics hub in Southeast Asia, has frequent port container transportation, and PVC canvas is needed to cover the top of containers (to resist heavy rain and sea wind and salt spray). Therefore, 1000D and 1300D high D value heavy-duty canvases are in great demand and must have "salt spray corrosion resistance" performance; Thailand's logistics is mainly land transportation (truck transportation of agricultural products, industrial accessories), and the canvas strength requirements are slightly lower, 840D, 1000D Specifications are more commonly used and need to be adapted to the irregular dimensions of the truck bed (such as the curved top of an extended truck).

In terms of manufacturing, Malaysia has a developed electronics industry and needs PVC canvas for workshop dust covers (it needs to be anti-static to avoid adsorbing dust and affecting electronic components); Thailand has an active auto parts manufacturing industry, and canvas needs to be used for equipment protection (it needs to be oil-resistant to prevent oil pollution during parts processing). Therefore, Malaysia prefers 500D canvas with "anti-static coating", while Thailand needs 840D canvas with "anti-oil coating".

3. What policy specifications and certification requirements need to be met to purchase or customize PVC canvas in the Malaysian and Thai markets?

Ignoring the policies and regulations of the two places may result in products that cannot be used in compliance or increase additional costs. The first is product certification. Malaysia requires: ① PVC canvas used in food contact scenarios (such as fruit transportation, grain storage) must pass SIRIM certification (Malaysian Institute of Standards and Industrial Research) to detect the content of harmful substances such as heavy metals and phthalates; ② Canvas used in outdoor construction scenarios (such as construction site protective sheds) must provide a fire performance test report (in compliance with MS 934 standards). Thailand requires: ① All imported PVC canvas must pass TISI certification (Thailand Industrial Standards Association) and tested for ultraviolet resistance (UPF ≥ 50+) and waterproof performance (water pressure ≥ 2000mm); ② Canvas used for agriculture (such as greenhouse covering) must additionally pass the "non-toxicity test" of the agricultural department to avoid contaminating soil and crops.

The second is environmental protection and tariff policies. Malaysia promotes "green logistics" and provides a 5%-10% import tariff reduction for canvas using "recyclable PVC materials" and "low VOC coatings" (environmental certification documents are required); Thailand's basic tariff rate for imported canvas is 8%-12%, but through the ASEAN Free Trade Area (AFTA) rules, if the product complies with "China - "ASEAN Origin Standard" (such as localization rate ≥ 40%), you can apply for a tariff reduction of 0%-5%. In addition, Thailand also requires imported canvas to apply for an "import license" (issued by the Foreign Trade Department of the Ministry of Commerce of Thailand) in advance. If a local dealer is entrusted, it must be confirmed that it has the "goods import rights" qualification.

4. For the usage scenarios in Malaysia and Thailand, what are the “localization” techniques for the installation and maintenance of PVC canvas?

Even if the product performance meets the standard, if the installation and maintenance do not meet the local characteristics, the service life will be shortened. From the installation point of view, it is rainy and windy in Malaysia. When installing outdoor canvas (such as storage sheds and tents), please pay attention to: ① The distance between fixed points should not exceed 1.2 meters (1.5 meters in ordinary areas), and be fixed with stainless steel bolts (to avoid rain corrosion); 2. Reserve 8-10cm of sagging at the edges of the canvas (1.5 meters in ordinary areas) 5cm) to prevent rain water from crushing the canvas; ③ Before the typhoon season, the fixing accessories need to be checked and additional windproof ropes (1 piece every 2 meters). Thailand has high temperatures in the dry season and heavy rain in the rainy season, so the installation techniques focus on: ① When installing truck canvas in the dry season, put insulation cotton at the contact point between the canvas and the metal of the carriage (to prevent the high-temperature metal from scalding the coating); ② When installing the outdoor shed canvas in the rainy season, the inclination angle needs to be ≥30° (25° in ordinary areas) to accelerate the rainwater from sliding off.

In terms of maintenance, in the high-humidity environment of Malaysia: ① Dry the canvas once every 2 months after use. If mildew spots appear, wipe them with neutral soapy water (washing powder is prohibited), apply anti-mold agent after drying; ② Store away from the ground (use a wooden frame to raise it by more than 30cm) to avoid ground moisture causing mold at the bottom. Thailand has a lot of sand and dust in the dry season and mud in the rainy season: ① Rinse the canvas surface with clean water every week during the dry season (to avoid sand and dust friction and wear of the coating); ② Check the seams of the canvas after the rainy season. If there is water seepage, use PVC special repair glue to paste the patch (the patch must be more than 5cm larger than the damaged area); ③ When storing, it is necessary to avoid heat sources (such as generators and heating equipment in warehouses) to prevent high temperatures from accelerating the aging of the coating.