I. What is Tarpaulin? Understand its definition and core values in one article

Tarpaulin (often called "tarpaulin" in Chinese) refers to a functional fabric that uses fiber fabric as the base fabric and is endowed with waterproof, wear-resistant, anti-aging and other properties through coating, lamination and other processes. Some finished products are also cut and sewn according to needs to form protective products that can be used directly (such as truck covers, equipment covers, tents, etc.). Its core value lies in "protection" and "adaptation" - it can not only resist damage to protected objects from external environmental factors such as rain, dust, ultraviolet rays, etc., but also adjust size, structure and performance according to the needs of different scenarios, becoming an indispensable basic tool in the operations of various industries.

From the perspective of use form, Tarpaulin can be divided into two categories: "basic fabric" and "finished tarpaulin": the basic fabric is mainly used for subsequent processing and needs to be cut and sewn according to specific needs; the finished tarpaulin is a directly formed protective product that can be used out of the box, such as common truck tarpaulins, container tarps, machine protective covers, etc. No matter what form it is, the core performance of Tarpaulin revolves around "durability" and "protection", and high-quality Tarpaulin products can often achieve a balance between these two core properties, while taking into account ease of operation and cost economy.

II. What are the common types of Tarpaulin? How to choose different materials?

There are many types of Tarpaulin on the market, which can be divided into multiple types according to the base fabric material and coating material. The performance of different types is significantly different, and the adaptation scenarios are also different. Mastering the classification characteristics is the basis for accurate selection:

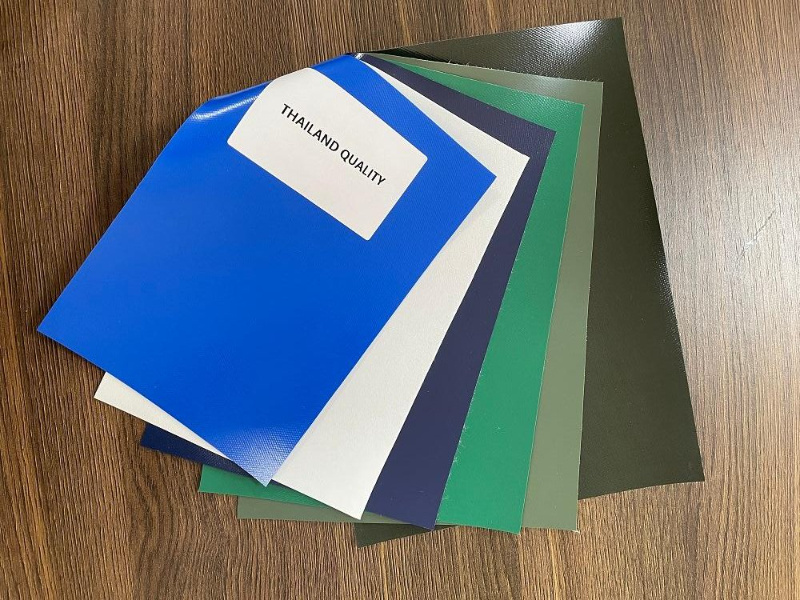

1. PVC Tarpaulin (polyvinyl chloride tarpaulin)

PVC Tarpaulin is one of the most widely used categories at present. It is made of polyester or nylon based fabric and coated with polyvinyl chloride resin. Its core advantages are strong waterproofness, good weather resistance, high tear resistance, the ability to maintain stable performance in the temperature range of - 20°C to 60°C, and a certain degree of acid and alkali corrosion resistance, making it suitable for long-term outdoor use or complex environmental protection (such as truck transportation, industrial equipment coverage, outdoor tents, etc.). In addition, PVC Tarpaulin has strong plasticity. By adjusting the coating thickness and adding functional additives (such as anti-UV agents, flame retardants), it can achieve special properties such as anti-UV and flame retardant, and adapt to more niche scenarios.

Professional manufacturers such as Qidong Good Tarpaulin produce PVC Tarpaulin covering multiple sub-categories such as PVC tarpaulin fabric, PVC mesh fabric, PVC canvas fabric, etc. It can not only provide basic fabrics, but also process them into finished products such as truck covers, trailer covers, fruit picking bags, etc., and support customized performance parameters according to customer needs, such as optimizing anti-fungal performance for the high temperature and high humidity environment in Southeast Asia, improving environmental compliance for the European market, and meeting the use needs of different regions.

2. PE Tarpaulin (polyethylene tarpaulin)

PE Tarpaulin uses polyethylene film as the main material, and some are compounded with woven fabric to enhance toughness. Its advantages include light weight, low price, and good flexibility. It is suitable for temporary protection scenarios (such as short-term cargo coverage, temporary awnings, etc.), but its durability and weather resistance are weak. It is prone to aging and brittleness in long-term outdoor use, and its tear resistance is lower than PVC Tarpaulin. It is not suitable for high-frequency or long-term protection needs.

3. Canvas Tarpaulin

Traditional Canvas Tarpaulin uses cotton fiber as the base fabric, which requires oil immersion, wax coating and other processes to achieve waterproofing; modern Canvas Tarpaulin mostly uses cotton blended base fabric, or composite PVC coating to improve performance. Its advantage is that it has good breathability and soft feel, and is suitable for scenes that require breathability (such as food storage, the inner layer of outdoor camping tents). However, pure canvas tarpaulin has poor waterproofing and weather resistance and requires regular maintenance. Canvas Tarpaulin with composite PVC coating (such as Qidong Good Tarpaulin's PVC canvas fabric) can improve waterproof and anti-aging properties while retaining breathability, broadening the scope of applications.

4. Other special types

In addition to the above three categories, there are also Tarpaulins for specific scenarios, such as fire-resistant tarpaulins (added with flame retardants, used in flammable and explosive environments), anti-static tarpaulins (used for transportation protection of electronic components), cold-resistant tarpaulins (optimized formula, suitable for low-temperature environments below - 40°C), etc. The production of this type of special Tarpaulin has high requirements on technology and raw materials, and usually requires professional manufacturers to customize it according to specific needs. For example, Qidong Good Tarpaulin can adjust the fabric formula and processing technology according to the customer's special protective needs to produce special-function Tarpaulin that meets industry standards.

III. The core points of purchasing Tarpaulin: avoid misunderstandings and choose the right product

Faced with various Tarpaulin categories, if users choose blindly, they are prone to problems of "insufficient performance" or "excessive waste". The following four core points can help users make accurate selections and improve procurement cost-effectiveness:

1. Clarify usage scenarios and core requirements

Before purchasing, you need to clearly understand the usage scenario of Tarpaulin (such as outdoor or indoor, transportation or storage), the characteristics of the object to be protected (such as whether it is afraid of moisture, sun, and corrosion) and the use cycle (short-term temporary use or long-term fixed protection), and determine the core performance requirements accordingly. For example:

Long-term outdoor trucking: focus on "waterproof, UV resistance, wear and tear resistance", and give priority to PVC Tarpaulin;

Short-term temporary food covering: If you need breathability, you can choose Canvas Tarpaulin; if you focus on waterproofing and have a limited budget, you can choose PE Tarpaulin;

Chemical equipment protection: PVC Tarpaulin that is “resistant to acid and alkali corrosion” needs to be selected, and flame retardant properties can be customized if necessary.

If you are unclear about your needs, you can consult a professional manufacturer. For example, Qidong Good Tarpaulin has more than 20 years of industry experience and can recommend adapted Tarpaulin types and performance parameters based on the scenarios described by customers. It can also provide free samples to help users visually verify whether the product meets their needs.

2. Focus on key performance indicators

The performance of Tarpaulin can be judged through key indicators. It does not require professional testing equipment and can also be initially evaluated through simple methods:

Waterproof: Pour water on the surface of the fabric, and the water beads of high-quality products will roll off quickly without penetration; rub the seams, and there will be no signs of glue opening or water seepage;

Tear resistance: Gently pull the edge of the fabric, high-quality products are not easy to deform, and can return to their original shape after letting go; lightly scratch the surface with a hard object, no obvious scratches or coating peeling off;

Weather resistance: Check whether the product has added anti-UV agents, anti-aging agents, or consult the manufacturer for its outdoor service life (the outdoor service life of high-quality PVC Tarpaulin is usually 5-8 years);

Thickness and weight: For the same type of Tarpaulin, thickness and weight are usually positively related to durability (for example, PVC Tarpaulin thickness ≥0.5mm is more suitable for long-term use), but it needs to be combined with the needs of the scene to avoid being too thick and affecting operation.

3. Identify product quality and avoid the trap of inferior quality

Some low-quality Tarpaulin on the market has the problem of "cutting corners", such as low base fabric density, thin coating, added recycled materials, etc., resulting in short service life and poor protection effect. When purchasing, you can initially identify by “looking, touching and smelling”:

Look: the surface of high-quality Tarpaulin is smooth, the coating is uniform, and there are no bubbles, impurities, or missed coatings; the base fabric has a clear texture, and there are no jumpers or broken wires;

Touch: It feels thick and elastic, and rebounds quickly after pressing; inferior products feel thin and brittle, or the coating is sticky;

Smell: High-quality Tarpaulin has no pungent odor (such as strong plastic smell, sour smell); inferior products may have pungent odor due to the use of recycled materials or inferior additives, and may also release harmful substances after long-term use.

4. Choose “fabric” or “finished product” as needed, taking into account both cost and efficiency

If the user has the processing ability, he can purchase Tarpaulin basic fabric and cut it by himself; if he needs to use it directly, or has special requirements for the structure of the finished product (such as non-standard size, special opening design), it is recommended to choose finished Tarpaulin. Professional manufacturers such as Qidong Good Tarpaulin can provide one-stop "fabric + finished product" services. They can not only provide basic fabrics, but also process them into truck covers, equipment covers, curtains and other finished products according to customers' size and structural requirements. The factory direct supply model can reduce the cost of intermediate links, while ensuring the performance consistency of fabrics and finished products, and avoiding the problem of mismatch between outsourced fabrics and processing technology.

IV. Scenario-based application of Tarpaulin: Adaptation skills from theory to practice

Tarpaulin has various application scenarios, and the usage methods and precautions in different scenarios are quite different. Mastering the adaptation skills can maximize the protective effect of Tarpaulin and extend its service life:

1. Logistics and transportation scenarios (trucks, trailers, containers)

Logistics and transportation are Tarpaulin’s core application scenarios, which need to focus on balancing “cargo protection” and “convenience of operation”:

Covering skills: First clean the sharp protrusions (such as metal corners, screws) on the surface of the carriage or cargo to avoid scratching the Tarpaulin; spread the Tarpaulin flatly to ensure that the cargo is completely covered without wrinkles (folds can easily accumulate water and cause leakage);

Fixing method: Use tightening straps and ropes to firmly fix the edges of the Tarpaulin to the carriage/container. It is recommended to wrap 2-3 turns around the corners and then tie them, or use metal buckles to reinforce them to prevent them from loosening due to bumps and wind resistance during driving;

Special needs: If you are transporting fresh food, flowers and other goods that require ventilation, you can choose Tarpaulin with mesh windows (such as Qidong Good Tarpaulin's PVC mesh fabric finished product), or reserve openable ventilation holes on the side of the Tarpaulin to avoid the direction of rain; if you are transporting valuable goods, you can choose finished Tarpaulin with anti-theft buckles to improve safety.

2. Industrial protection scenarios (machines and equipment, workshop warehousing)

In industrial scenarios, Tarpaulin is mainly used to protect equipment from dust, moisture, and corrosion. The usage method needs to be adjusted according to the characteristics of the equipment:

Large equipment: Give priority to "detachable" finished Tarpaulin, with access openings and heat dissipation holes reserved to facilitate equipment maintenance and heat dissipation; if the equipment has protruding parts (such as pipes, valves), special-shaped Tarpaulin can be customized to ensure fit and protection;

Precision equipment: You need to choose Tarpaulin with "good dustproofness and no lint" to prevent dust or fibers from entering the inside of the equipment and affecting the operation; if the equipment is in an acid-alkali environment (such as a chemical workshop), you need to use acid-alkali-resistant PVC Tarpaulin, regularly check whether the coating is damaged, and replace it in time;

Storage protection: When covering shelf goods, Tarpaulin needs to hang down to the ground 10-20cm to prevent dust from entering from the bottom; if the storage environment is humid, moisture-proof agent can be placed inside the Tarpaulin to improve the protection effect.

3. Agricultural production scenarios (crop coverage, breeding protection, picking assistance)

The demand for Tarpaulin in agricultural scenarios is both “protective” and “practical”. Common applications and techniques are as follows:

Crop covering: For anti-freeze in winter, you can choose thickened PVC Tarpaulin, and the edges of the cover are compacted with soil; for summer shading, you can choose PVC mesh fabric, which takes into account both shading and ventilation to avoid crop burns;

Breeding protection: The tarpaulin of livestock and poultry breeding sheds needs to be made of PVC Tarpaulin that is “anti-aging and easy to clean” to facilitate regular flushing and disinfection; for rainproof sheds for aquaculture, it is necessary to ensure that Tarpaulin has good waterproof properties, and at the same time, vents are reserved to avoid stuffy heat in the shed;

Picking assistance: Fruit picking bags (such as the finished products customized by Qidong Good Tarpaulin) need to be lightweight and flexible PVC Tarpaulin. The opening is designed with an elastic closure to facilitate the operation of picking workers and reduce fruit damage.

4. Outdoor scenes (camping tent, awning, emergency rescue)

Tarpaulin in outdoor scenes needs to take into account both "protection" and "portability". When using it, you need to pay attention to:

Camping tent: It is recommended to choose PVC Tarpaulin with high waterproof level for the outer layer of the tent, and breathable Canvas Tarpaulin for the inner layer. When setting up, make sure the tent is firmly fixed, and the corners are tightened with ground nails and ropes to deal with sudden wind and rain;

Awning: PVC mesh fabric or PVC Tarpaulin with sunshade coating is preferred to take into account both sunshade and ventilation; the brackets must be made of stable materials to avoid strong winds causing the shed to collapse;

Emergency rescue: For emergency shelter, you need to choose PVC Tarpaulin that is “light and easy to deploy”. Some professional rescue Tarpaulin will also add reflective strips to improve safety at night.

V. Tarpaulin maintenance and upkeep: extend life and reduce costs

The service life of Tarpaulin not only depends on product quality, but also is closely related to daily maintenance. Correct maintenance methods can extend the service life of Tarpaulin by 2-3 years and reduce repeated purchase costs:

1. Precautions for daily use

Avoid damage from sharp objects: When covering goods or equipment, clean the sharp protrusions on the surface first, or place a soft cloth on the protrusions; when transporting Tarpaulin, avoid dragging it over rough surfaces (such as gravel roads, cement floors);

Avoid overload pulling: When fixing the Tarpaulin, tighten the rope to a moderate degree to avoid excessive pulling that may cause fabric deformation and seam cracking; if the Tarpaulin shakes violently in strong winds, you can temporarily loosen part of the rope to reduce wind resistance damage;

Keep away from high temperature and fire sources: Tarpaulin made of PVC and PE is not resistant to high temperatures and needs to be kept away from high-temperature objects such as heaters, stoves, exhaust pipes, etc. It is prohibited to smoke or use open flames near Tarpaulin to prevent burning or melting.

2. Cleaning and maintenance methods

Regular cleaning: After dust and oil accumulate on the Tarpaulin surface, need to be cleaned in time to avoid corrosion of the coating; when cleaning, use clean water and a soft brush to scrub gently, and strong acid and alkali detergents (such as washing powder, dishwashing liquid) are prohibited; oil stains can be wiped with a dry cloth first, and then rinsed with clean water;

Storage after drying: After Tarpaulin is used, it needs to be dried thoroughly before being folded or rolled up for storage to avoid the growth of mold in a humid environment (mold will damage the coating and lead to a decrease in waterproofing); if it cannot be dried in rainy weather, it needs to be dried in time after the weather clears up;

Regular inspection: Check Tarpaulin once a month, focusing on vulnerable parts such as seams, fixed rope holes, and opening zippers; if the seam tape is found to have fallen off, apply special PVC waterproof glue to repair it; if the rope hole is damaged, you can subsidize a small piece of Tarpaulin for reinforcement; if the zipper is stuck, apply paraffin wax to lubricate it, and replace it in time if it is damaged.

3. Storage tips

Storage environment: Choose a dry, ventilated storage location without direct sunlight (such as warehouse shelves), avoid moisture (to prevent mildew), high temperatures (to prevent aging), and direct sunlight (to accelerate fading and brittleness);

Folding and placement: When folding Tarpaulin, avoid squeezing it hard and fold it gently according to the fabric texture to reduce creases; you can also roll up Tarpaulin and store it to avoid aging and cracking of the local fabric caused by long-term folding; keep away from sharp objects when storing to prevent scratches;

Batch storage: When an enterprise stores Tarpaulin in batches, it can be stored according to "frequency of use" and commonly used finished products should be placed in easy-to-access locations; if the storage period is long, it needs to be taken out to dry once every 3 months to check the quality status.